Selexible Plastic

swimming pool

1pcs

clear, transparent

1220*2440mm, 2000*3000, and customized from width 600~2000mm, length 2000~12000mm

10mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm, 80mm, 100mm, 120mm, 150mm, 200mm, 250mm, 300mm, 400mm, 500mm, 600mm

Acrylic,100% virgin lucite or Mitsubishi

customized

High Surface Hardness

High light transmission(up to 96%)

| Availability: | |

|---|---|

| Quantity: | |

While a standard glass panel in a pool cannot be repaired if scratched or damaged, acrylic panels can be repairedon-site without the need to drain the entire pool.

Acrylic is a lightweight and durable material, weighing half as much as tempered glass.

Acrylic is highly malleable, making it easy to shape for radius designs.

When designing your acrylic panel, bonding technologies enable the creation of panels with unlimited sizes.

Impact resistant: Acrylic polymer exhibits 17 times greater impact resistance compared to tempered glass.

The design is engineered with a safety factor greater than 12.5.

With a minimum of 92% light transmission, acrylic maintains consistent transparency regardless of its thickness.

For more, you can download the pdf. as bellow

acrylic panels for swimming pools.pdf

acrylic panels for swimming pools.pdf

Acrylic panels offer superior durability compared to tempered glass, eliminating the risk of cracks or "spiderweb" dings in your window or custom pool design. When it comes to repairs and installation, acrylic surpasses glass. Unlike scratched glass, acrylic can be easily repolished and refinished without the need to drain water.

The refractive index of acrylic is the same as water, making the panel thickness virtually indiscernible when looking through it. It appears incredibly thin, almost like paper.

Outdoor acrylic pool panels exhibit exceptional durability, being highly resistant to breakage and impact. Acrylic's remarkable formability allows for limitless creative possibilities, enabling the transformation of any imaginative concept into reality.

With acrylic, size and scalability are virtually unlimited. Its outstanding visibility and clarity are unmatched, as it allows an impressive 92% light transmission. This makes it possible to create acrylic walls that beautifully merge with the surrounding environment in see-through swimming pools.

Size | Thickness | Size | Thickness |

1300*2500mm | 20~70mm | 1800*5000mm | 30~150mm |

1350*2650mm | 20~100mm | 2100*5500mm | 30~150mm |

1450*2700mm | 20~100mm | 3000*6200mm | 50~250mm |

1600*2600mm | 20~100mm | 3000*6700mm | 50~250mm |

1650*3150mm | 20~100mm | 3000*8200mm | 80~250mm |

2200*3200mm | 20~110mm | 3000*8700mm | 80~250mm |

1650*3500mm | 30~100mm | 3000*11500mm | 100~250mm |

2750*4250mm | 30~130mm | 3700*8100mm | 120~300mm |

| Item | Description |

| Material | Acrylic,100% virgin lucite or Mitsubishi |

| Color | Clear |

| Shape | Customized |

| Surface | High Surface Hardness |

| Light transmission | High light transmission(up to 96%) |

| Shipment | worldwide by sea or by air |

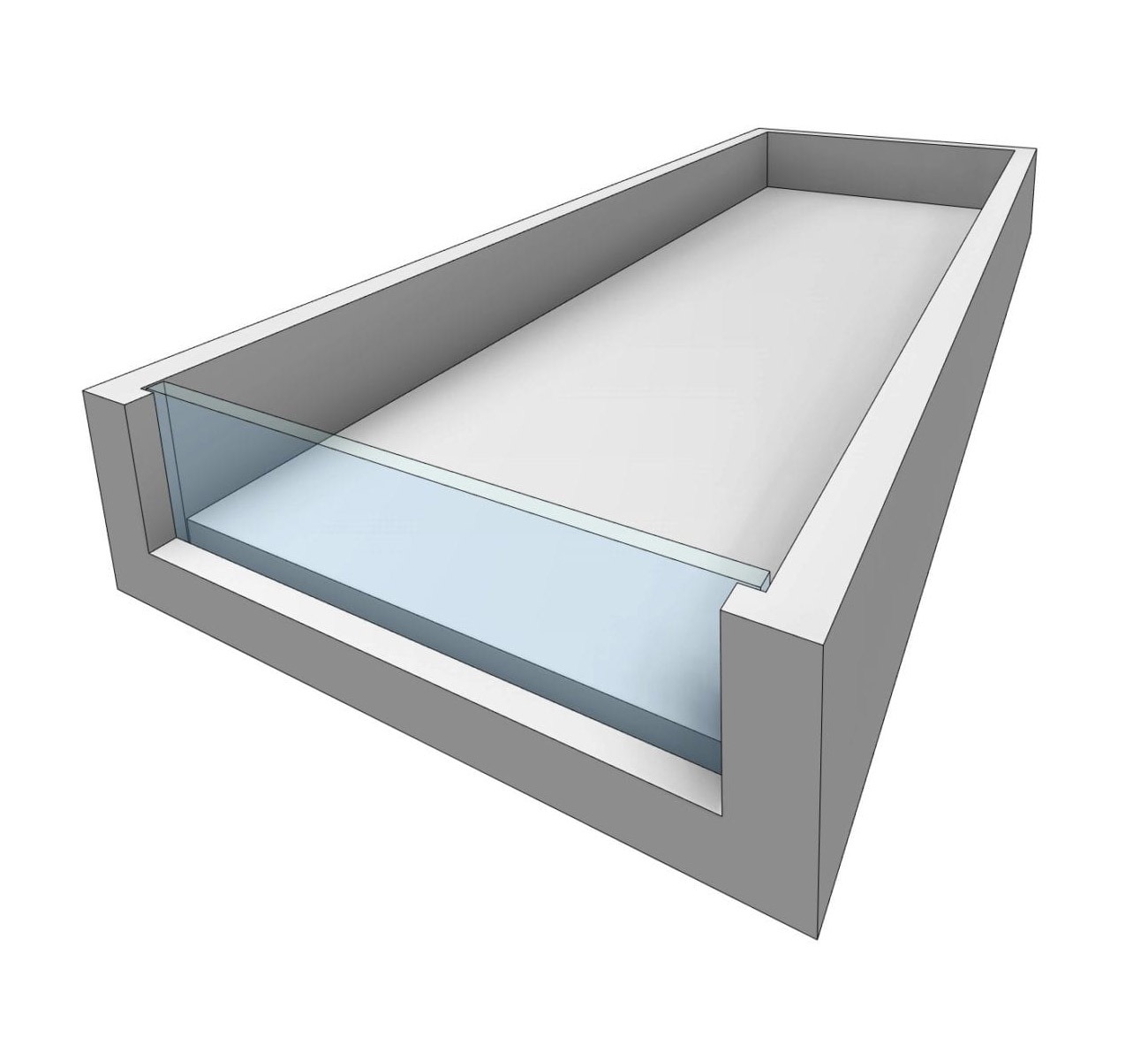

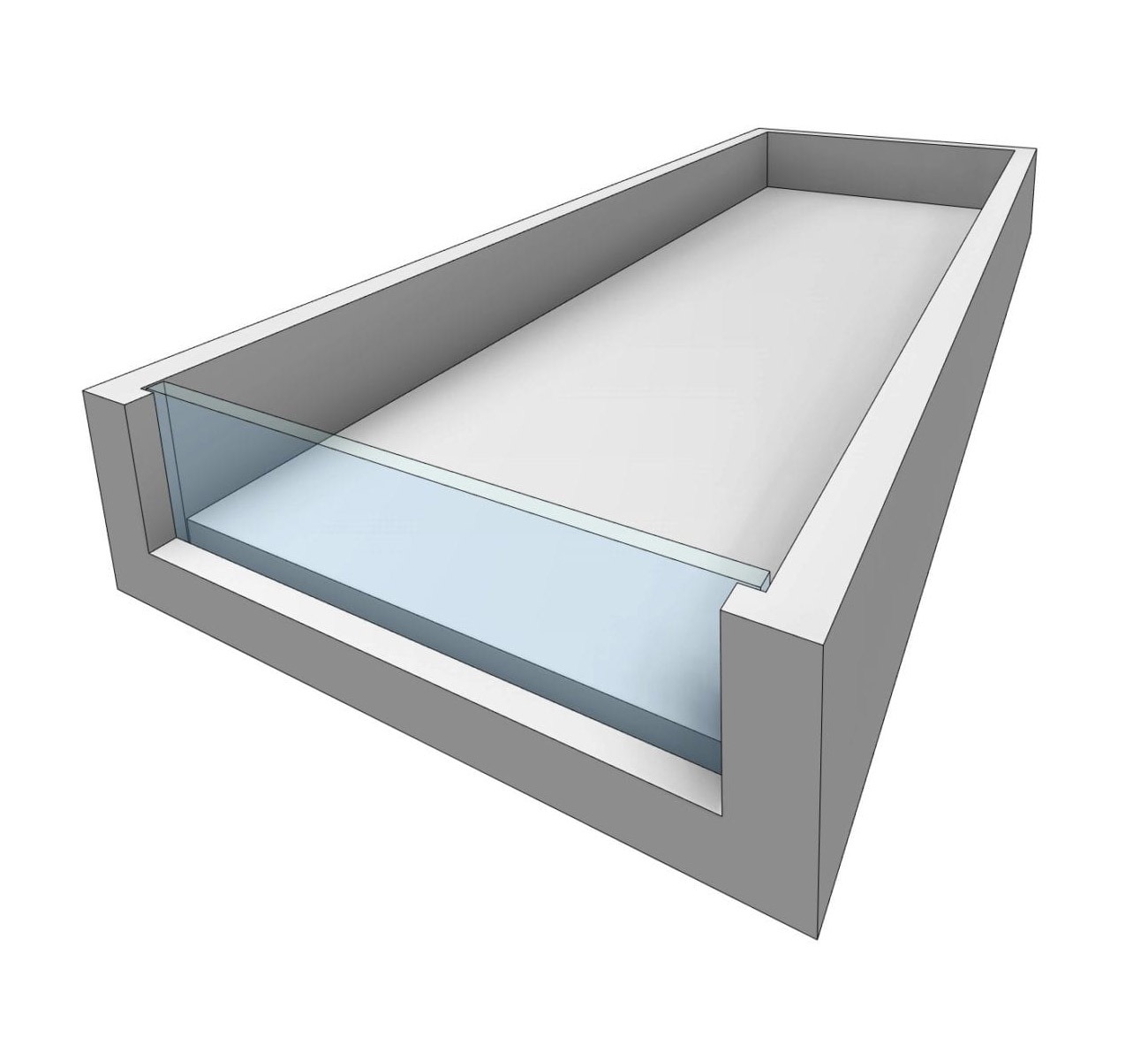

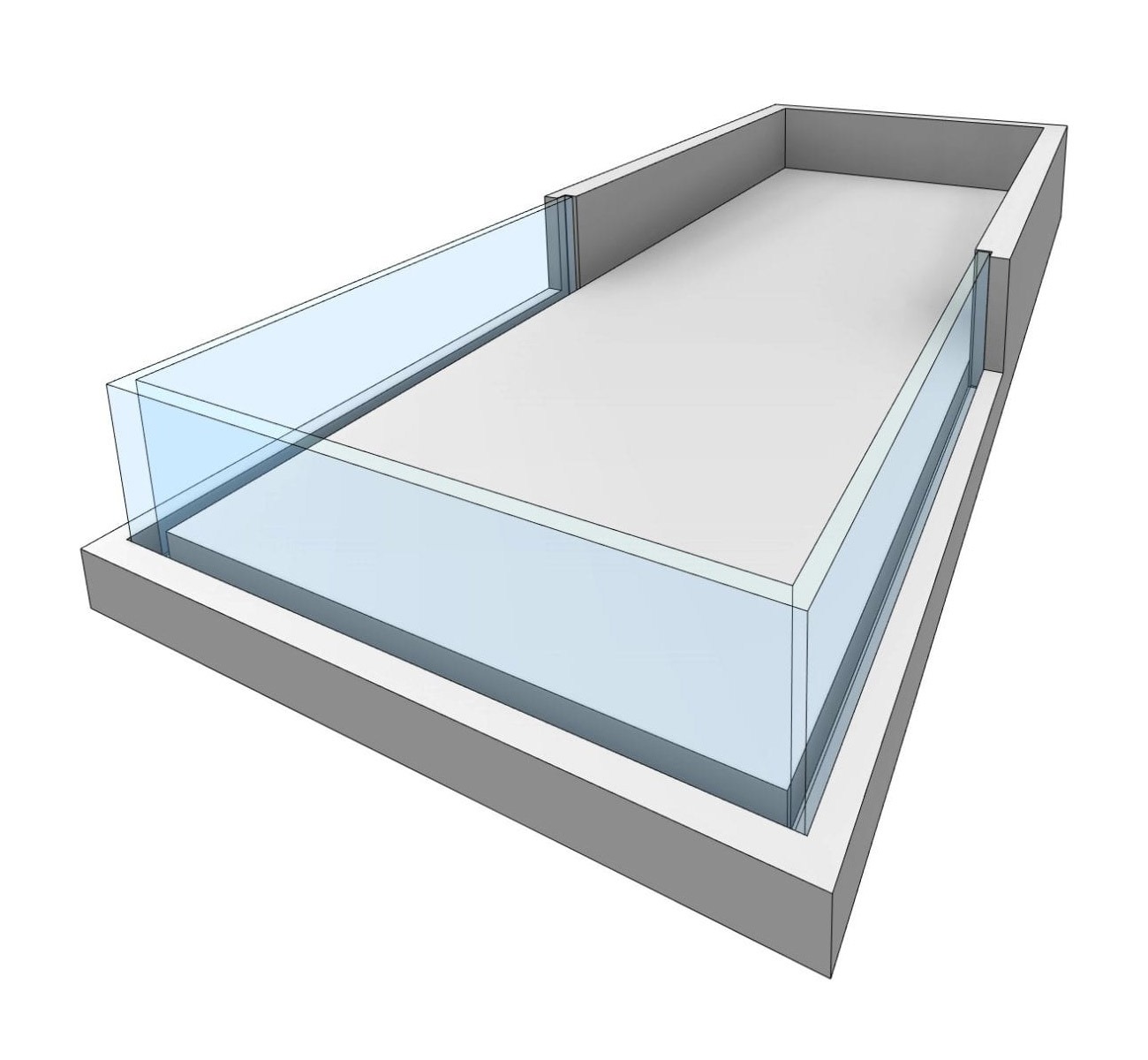

These panels are ideal for end placement, particularly when positioned towards scenic vistas. They are a popular selection for properties located alongside canals. Additionally, they are perfect for cantilevered pools. These panels are set within recesses on three sides, allowing for flexibility in water level placement, either below the top edge or opting for a "wet edge" effect for infinity pools.

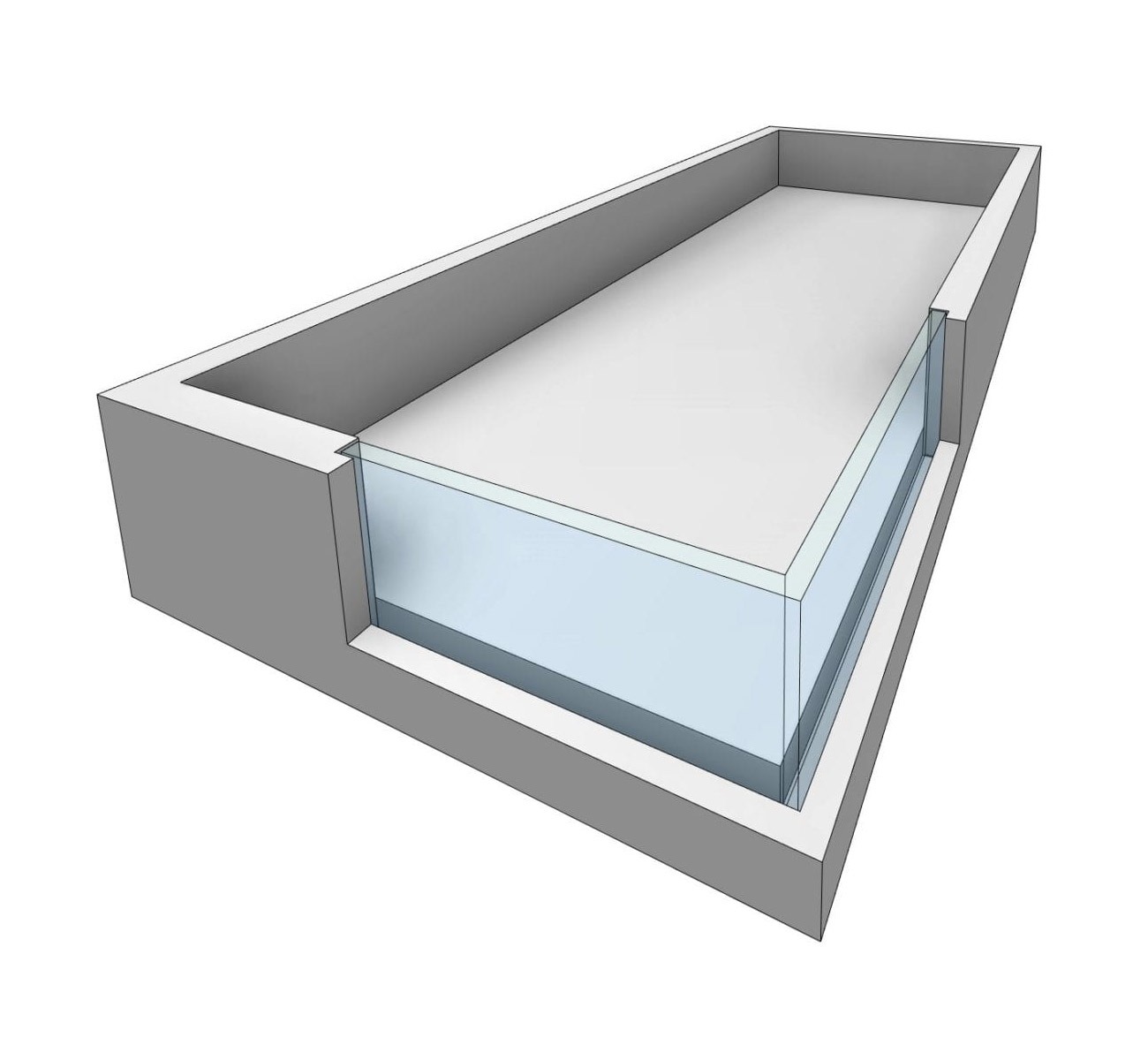

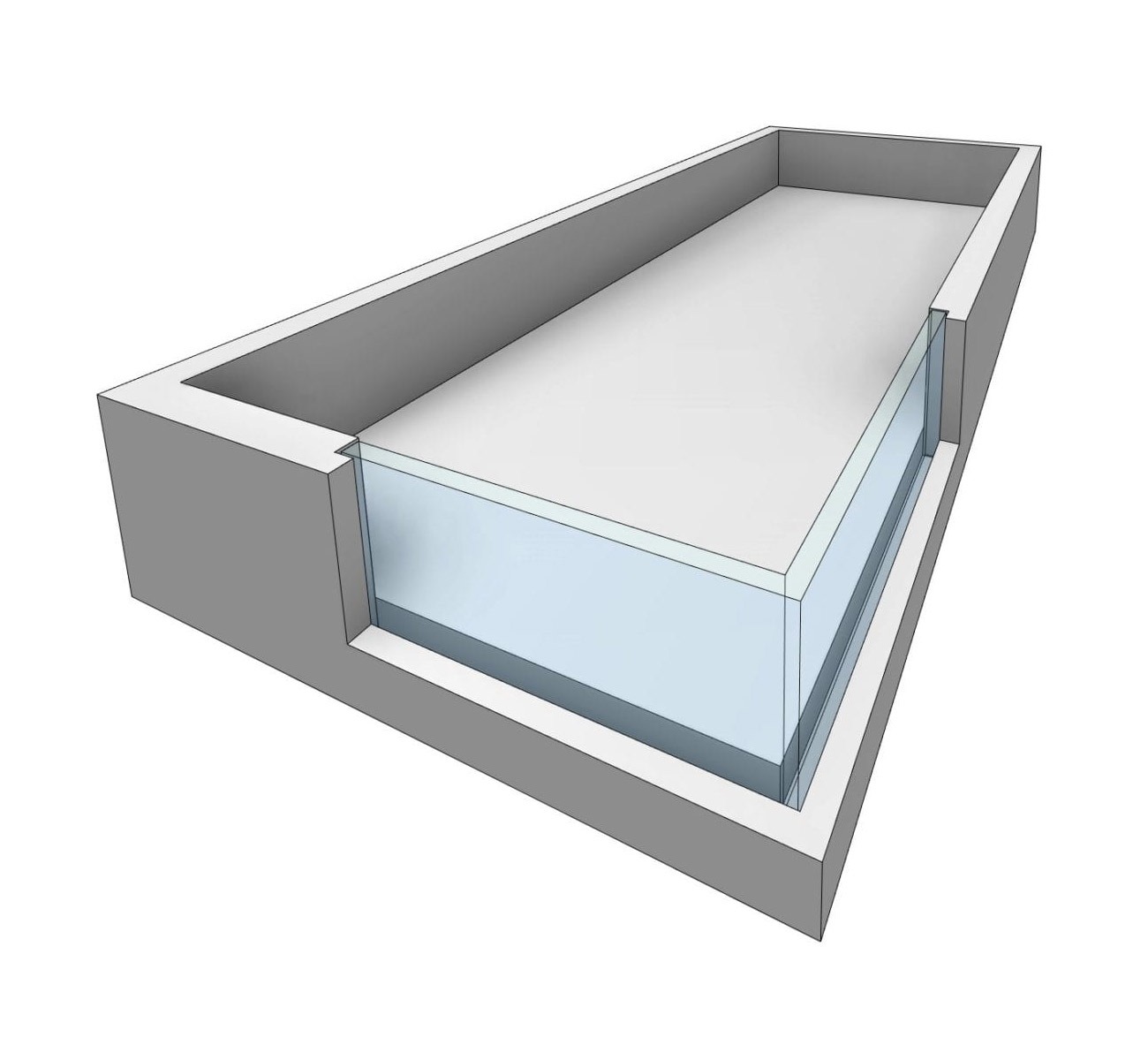

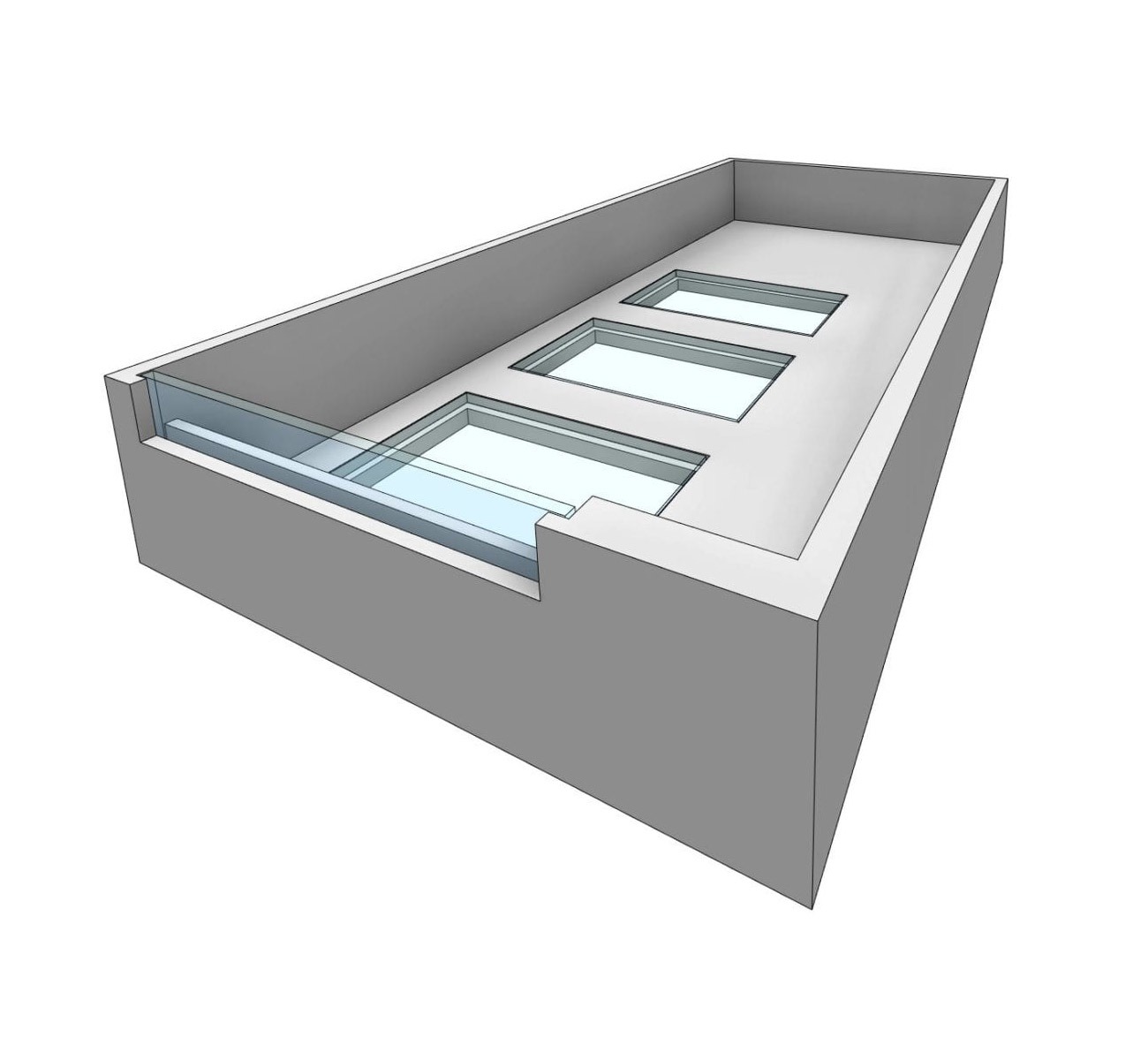

Two panels are securely bonded at the corner using chemical bonding techniques. This design is also referred to as an "L-Shaped" window. The panels are skillfully set within recesses on three sides. You have the option to set the water level below the top edge or choose a "wet edge" configuration for infinity pools.

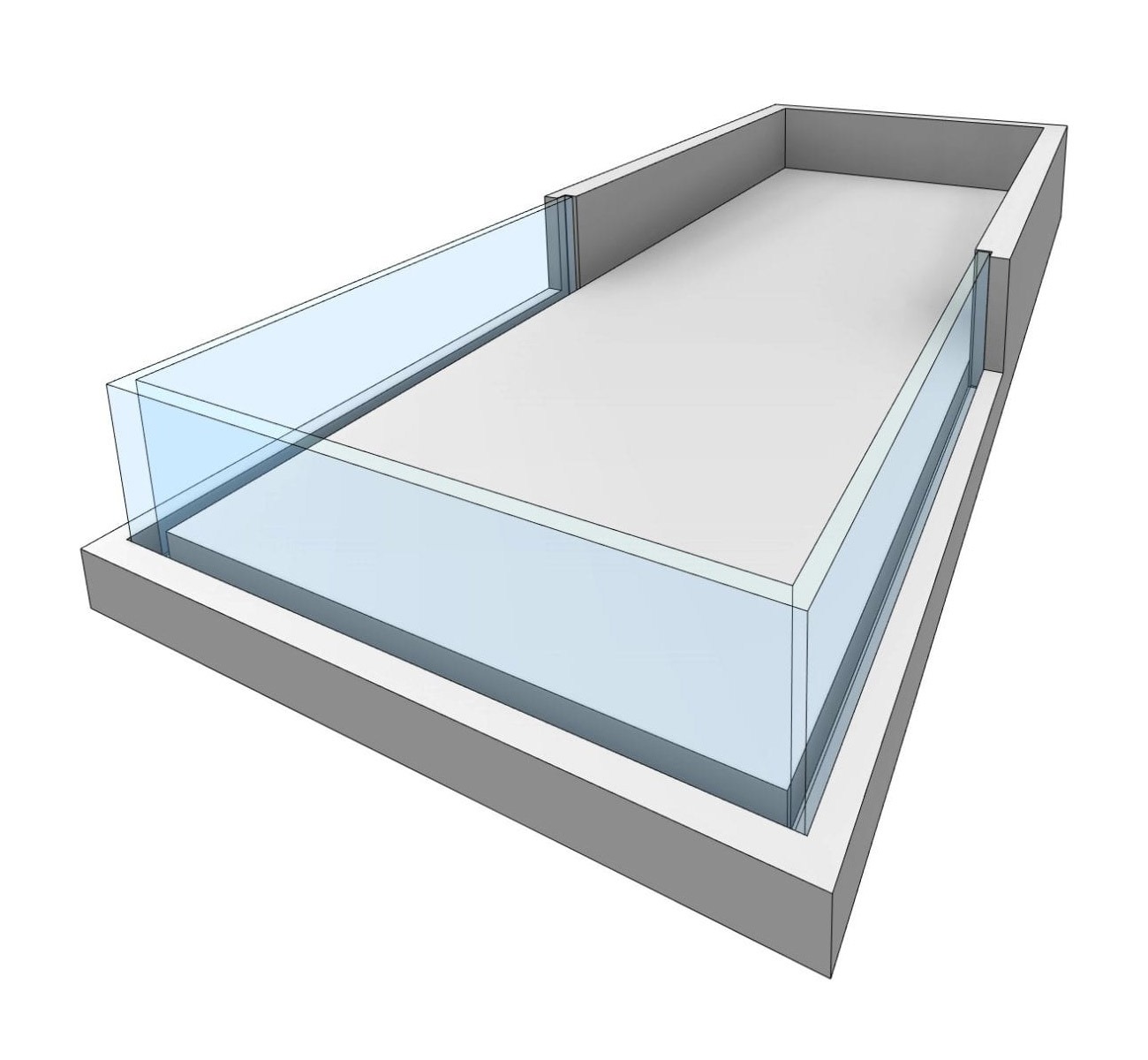

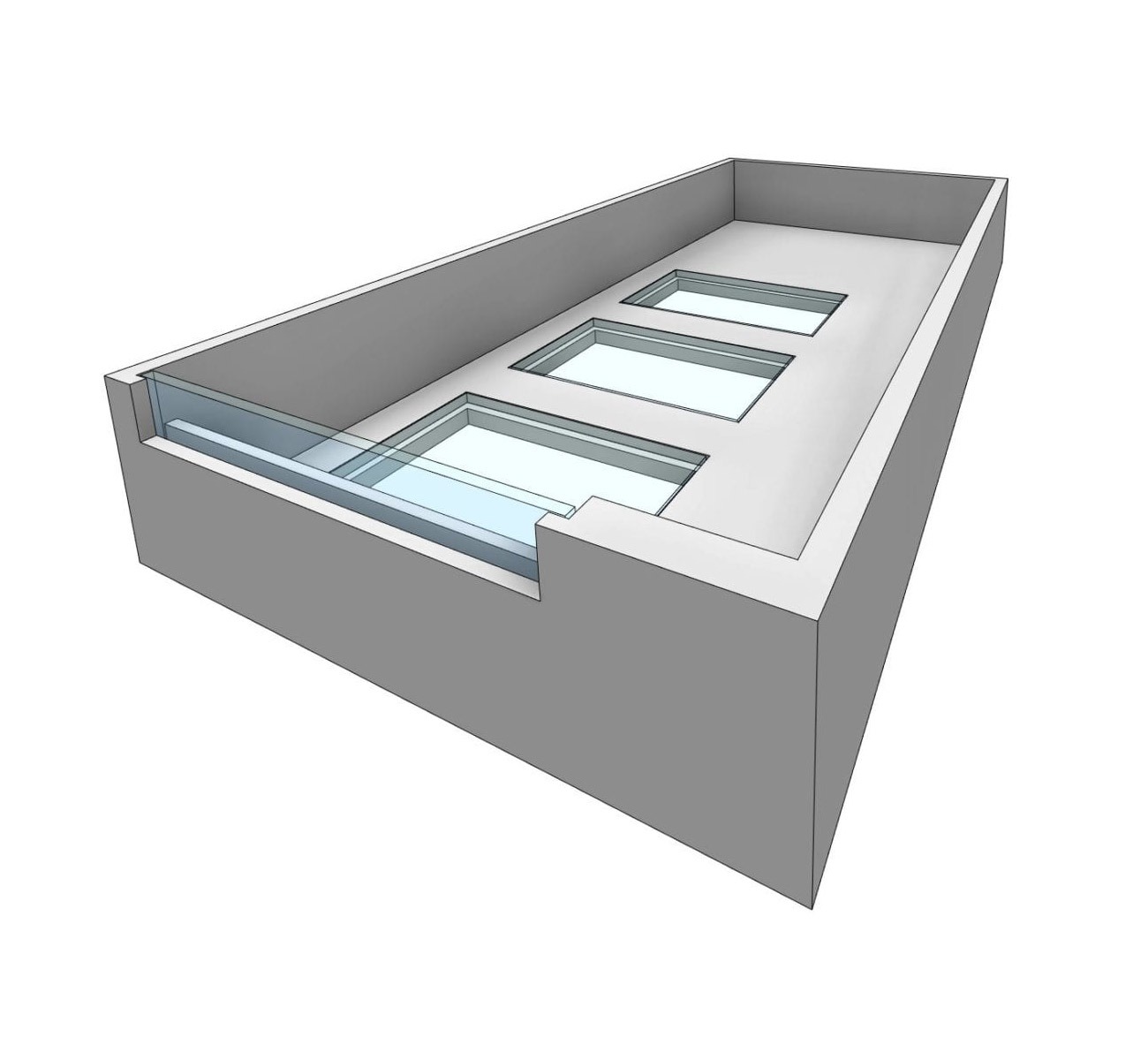

Three panels are expertly chemically bonded at two corners, creating a truly spectacular design suitable for premium properties. These panels are set within recesses on three sides, further enhancing their visual appeal. You have the flexibility to set the water level below the top edge or opt for a captivating "wet edge" effect in infinity pools.

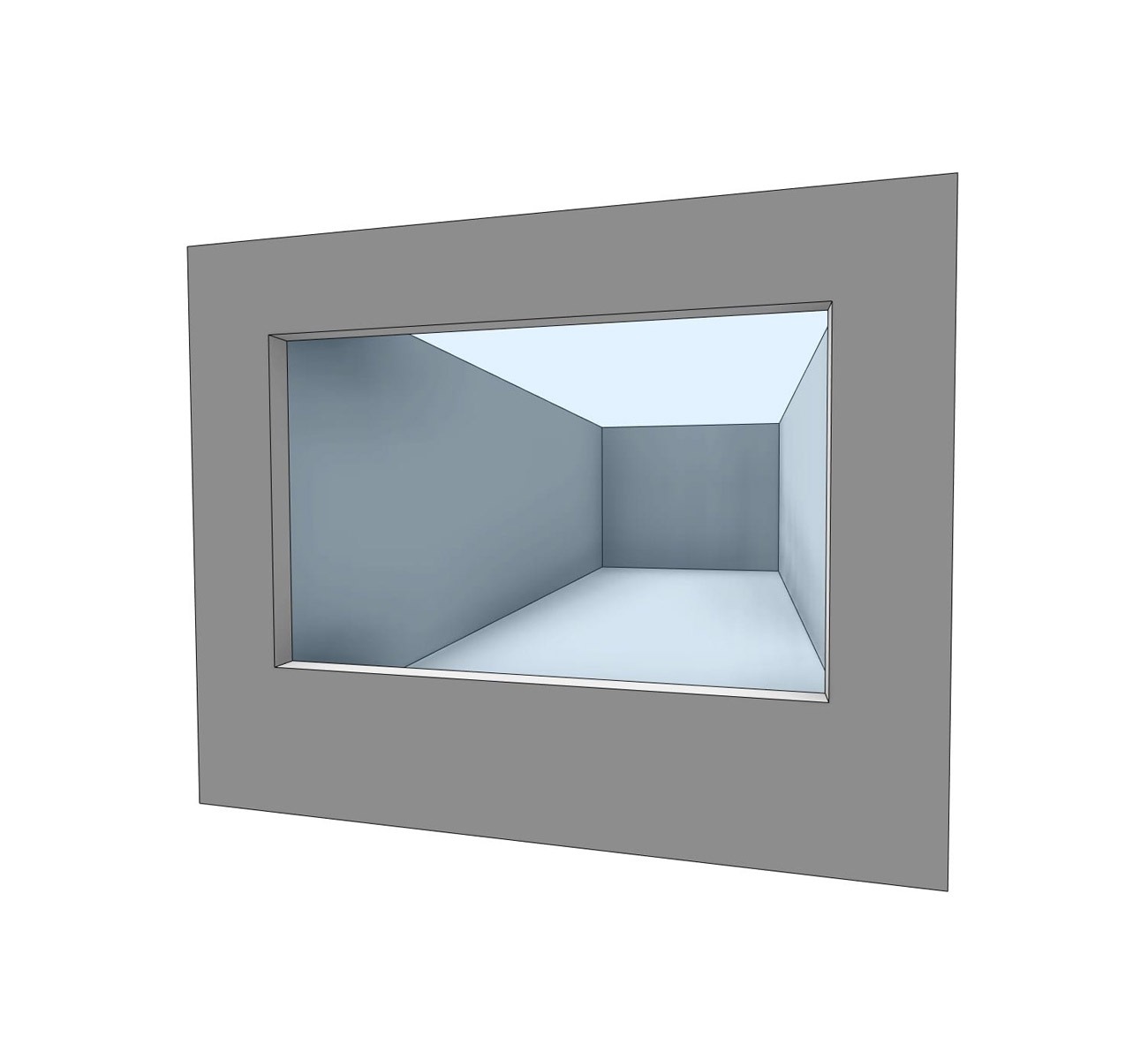

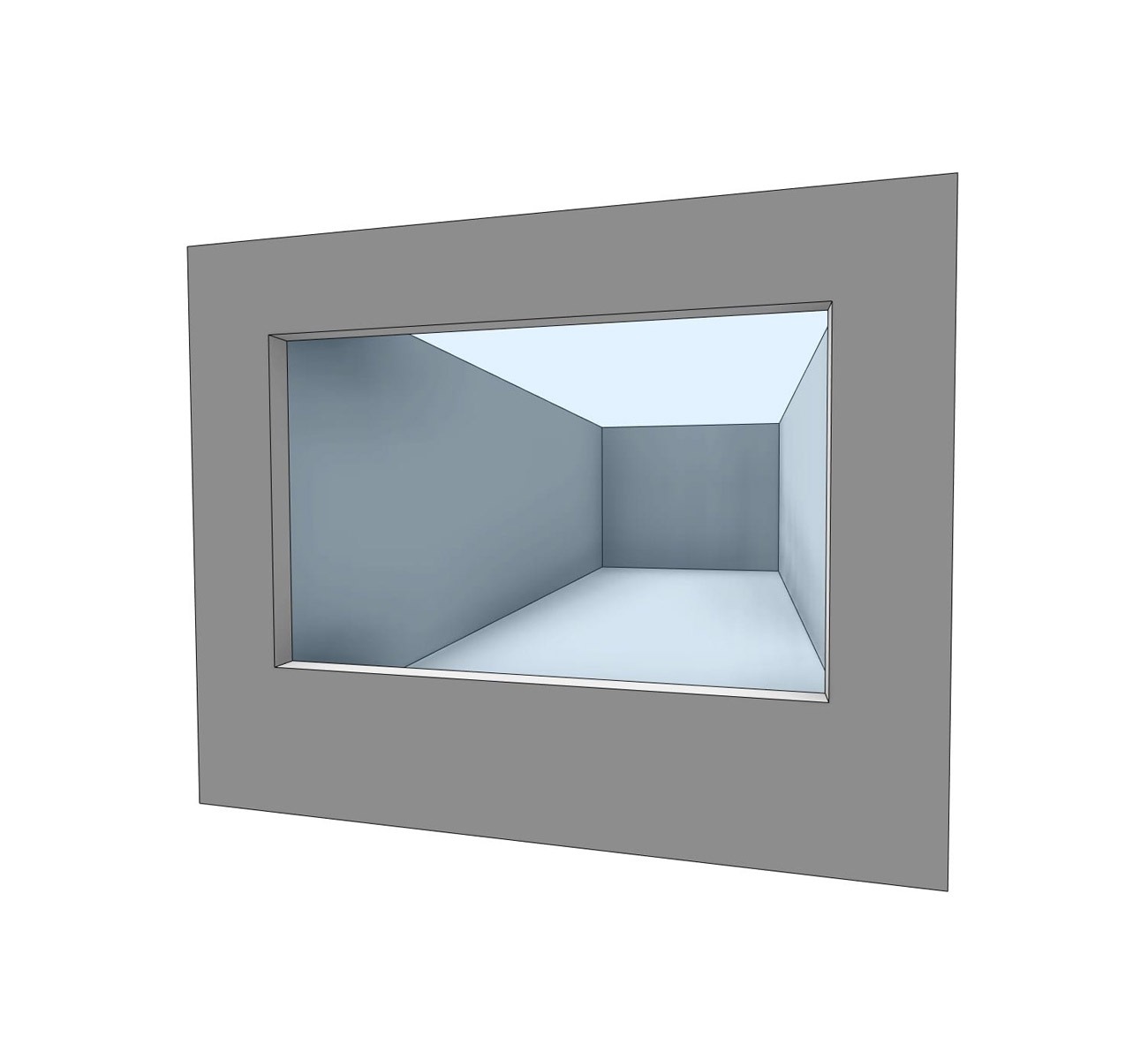

This option is widely favored as a window for interior spaces, particularly those adjoining lounge or entertainment areas. The presence of a four-sided rebate ensures exceptional durability, making it ideal for large panels requiring additional strength.

Edge panels are elegantly designed as shallow 3-sided panels, serving as a stunning final touch to your pool. Flour panels, on the other hand, are particularly suitable for cantilevered pools, or they can be utilized to create captivating underwater skylights, adding a touch of allure to rooms and spaces located beneath the pool.

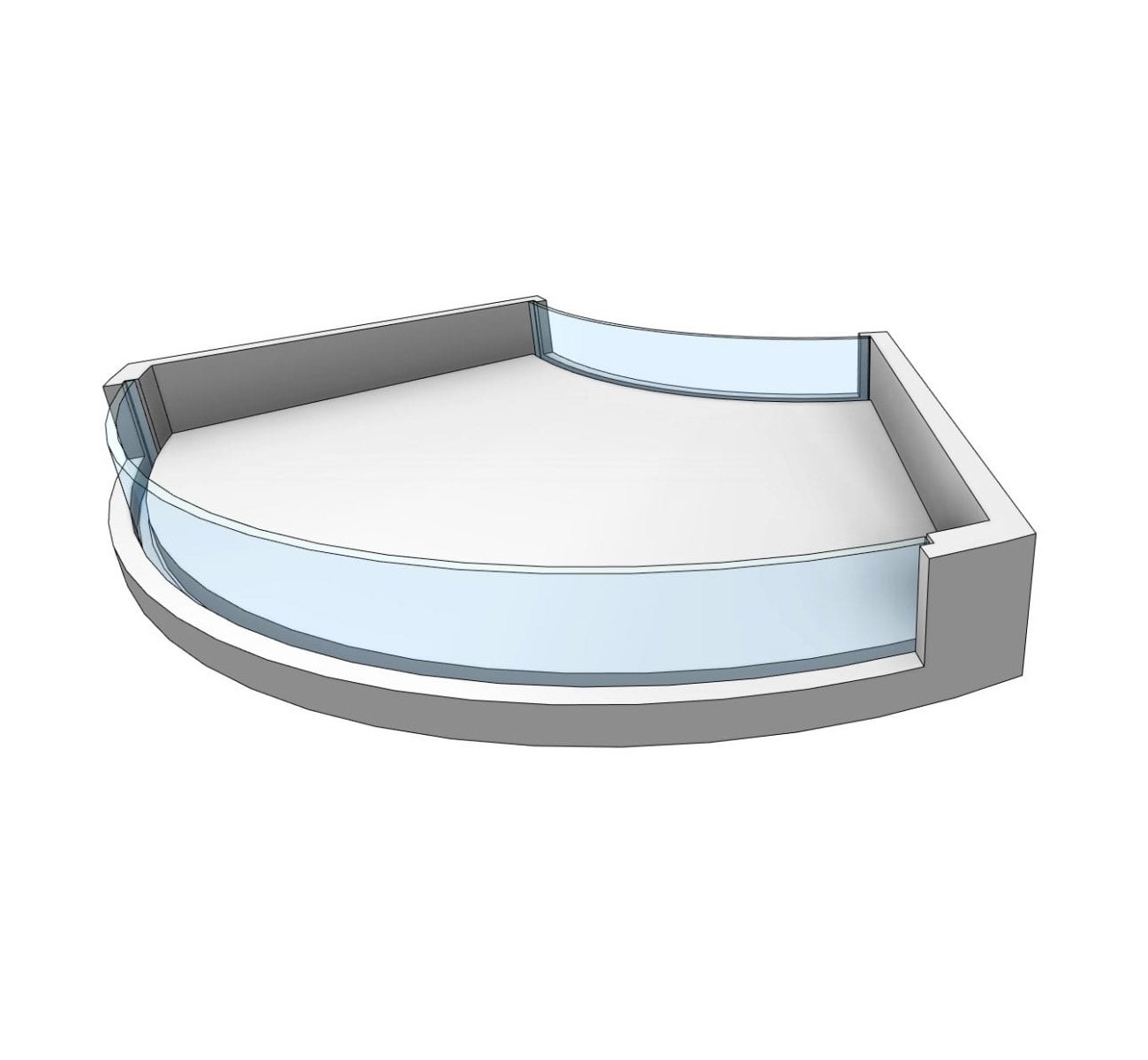

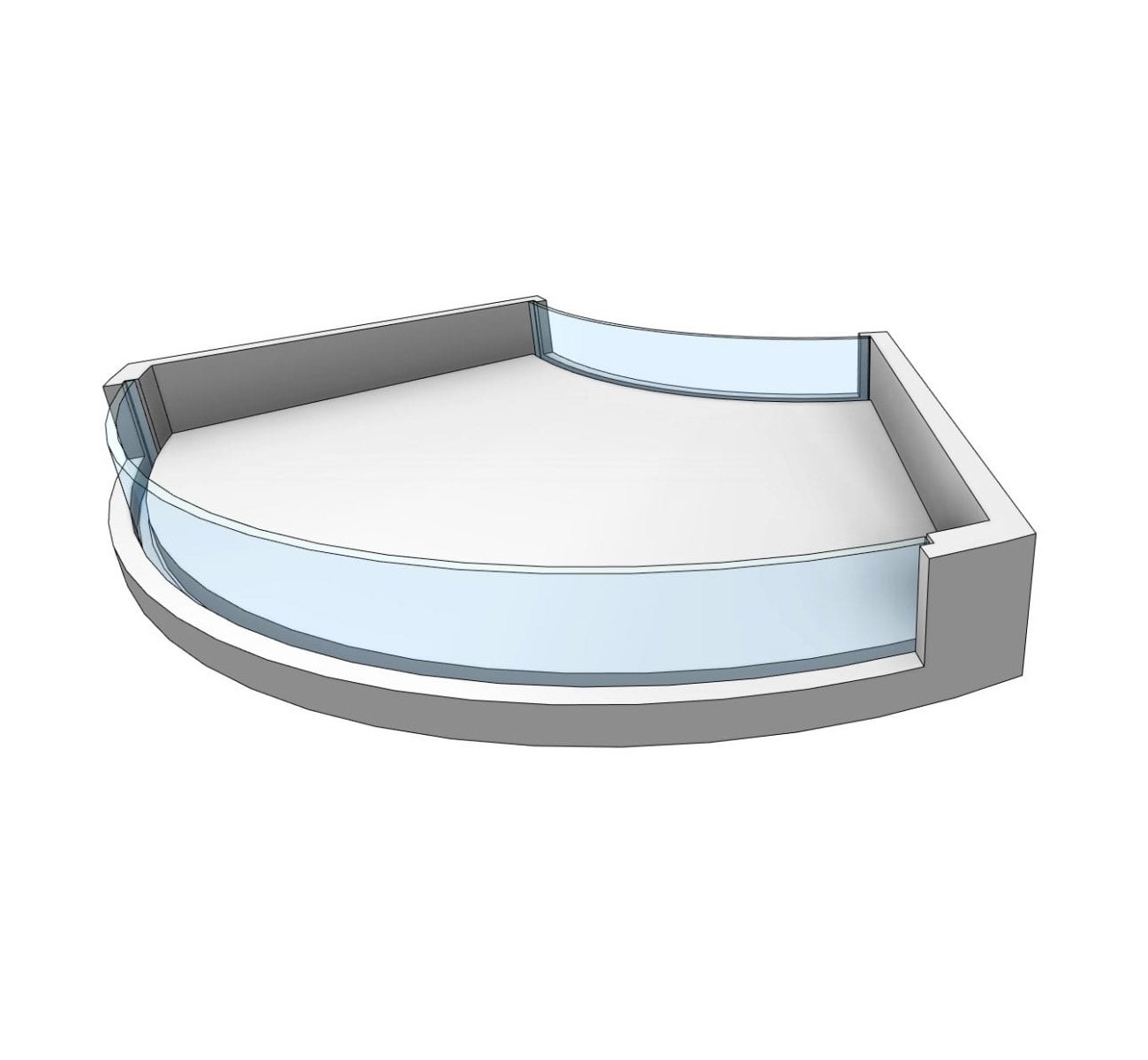

Swimming pools come in various shapes beyond square or rectangular designs! Acrylic can be skillfully molded to form both small and expansive curved sections, allowing for endless possibilities. You have the flexibility to choose between options with 3 or 4-sided rebates, providing further versatility in pool customization.

Absolutely.

When it comes to enhancing the efficiency, functionality, and quality of plexiglass swimming pool components in aquatic environments, various surface treatments are available.

Some popular coatings that can be applied to your acrylic pool walls include:

This treatment helps prevent moisture or fog from accumulating on the surface of the plexiglass pool panel, ensuring optimal clarity at all times.

This method reduces or eliminates excess or unwanted light, particularly beneficial for clear plexiglass panels or pools with lighting features.

Applying this coating helps protect the plexiglass surface from the damaging effects of ultraviolet rays, which can lead to distortion and discoloration.

This treatment prevents abrasive materials from causing unsightly marks on the plexiglass, maintaining its visual appeal.

These surface treatments contribute to the overall performance and longevity of plexiglass swimming pools.

Surely.

Here are all the reports and certificates that related with our acrylic sheets for swimming pool:

Chemical Resistant Report

Clarity Report

Data Sheet for Acrylic Sheets for Swimming Pool

Warranty Report for Acrylic Sheets for Swimming Pool

SGS Certificate of Transparency and Haza(Chinese version with translation)

SGS certificate of Aging by Light(Chinese version with translation)

* Export standard package or as clients' request to pack(usually in wooden or plastic pallets)

* We can deliver the goods or port or to door(customer's address) through sea shipping, air shipping or express.

Answer: Our acrylic pool windows are exclusively crafted using 100% Virgin Lucite MMA Raw Materials, ensuring UV resistance and exceptional quality.

Answer: Typically, our delivery time for Acrylic Pool Windows is 7-10 working days after receiving a 50% deposit payment. If you require additional machining services for the panel, we can utilize our CNT Machining Center to accommodate your specific drawing or machining requirements, which may slightly extend the delivery time. The final delivery time for Acrylic Pool Windows will be confirmed with you before you proceed with placing the order.

Answer: We provide a minimum 20-year warranty against any yellowing or crazing for our acrylic pool windows.

For the warranty , you can download the pdf. as bellow

warranty report for 30mm acrylic sheet.pdf

warranty report for 30mm acrylic sheet.pdf

The viewing area refers to the visible portion of the acrylic panel. While the panel itself is larger, as some of the acrylic is used for the rebates surrounding the windows, the viewing area is the specific section that can be seen.

Certain construction companies, pool builders, and acrylic installers may independently carry out their own calculations to determine the specifications for acrylic panels. In such cases, they provide us with comprehensive panel dimensions, including the desired thickness.

Alternatively, we calculate the appropriate thickness based on the information you provide, such as the dimensions of the viewing area, the distance between the water level and the top of the viewing area, and the number of rebates supporting the panel.

When we offer thickness recommendations, we generally follow a two-step process. Initially, we establish an estimated budget for your approval, and subsequently conduct a more detailed analysis to validate the initial calculations. The second stage may involve adjustments to the recommended thickness as necessary.

A Plexiglass Swimming Pool refers to a structure made from a transparent, shatterproof, and flexible thermoplastic material. It is specifically designed to create distinctive wall surfaces for various types of swimming pools, suitable for both indoor and outdoor installations. These pools are available in a wide array of options, including different designs, sizes, color shades, shapes, and more.

The ideal thickness of a Plexiglass Swimming Pool generally varies based on several factors, primarily architectural considerations. The shape and topography of the pool also play a significant role in determining the appropriate thickness for this pool component. Additionally, the projected water pressure is a crucial factor in determining the suitable thickness for a plexiglass swimming pool.

In most cases, the recommended thickness for this item typically falls within the range of 100mm to 150mm. This range is generally suitable for standard swimming pools. However, it is important to note that the actual thickness may undergo further evaluation and adjustment based on specific developmental considerations and individual factors.

When installing acrylic sheets for swimming pools, it is crucial to consider important aspects such as the size and design of the pool. These factors should align with the dimensions of the plexiglass to ensure a proper fit.

The installation process begins by using a suitable power tool to rebate the pool's surface, which depends on the nature of the pool's structure. Next, patching the rebates is essential to stabilize the anchor effect and enhance a unified core surface.

Using an epoxy paint, re-patch the rebates with silicone, taking care to prevent scratches on the plexiglass surface during installation. Before positioning the plexiglass panel, utilize a laser beam to ensure precise placement.

Once the panel is in position, reinforce all potential pressure points, particularly at the joints, and allow adequate time for curing. This ensures a strong and durable installation.

By following these steps, you can successfully install acrylic sheets for swimming pools, creating a visually appealing and long-lasting result.

The growing popularity of plexiglass indicates its superiority over fiberglass swimming pools in various aspects. One notable advantage is the ease of installation.

Plexiglass is lightweight, weighing almost half as much as fiberglass. This makes it easy to handle, transport, and install without requiring significant support.

Additionally, plexiglass exhibits superior impact resistance compared to fiberglass. It is approximately 17 times stronger, reducing the risk of cracking and breakage.

In terms of resilience, plexiglass outperforms fiberglass in multiple areas. It offers higher resistance to UV rays, corrosion, temperature changes, and weather conditions.

Plexiglass panels provide more options for customization, including variations in color shades, finishing, and shapes, allowing you to achieve your desired wall surface for the pool.

Optical clarity is also superior in plexiglass swimming pools, allowing up to 92% of light transmission compared to approximately 84% in fiberglass.

It's important to note that plexiglass has a softer surface than fiberglass, which makes it more susceptible to scratches when in contact with abrasive items.

Overall, plexiglass stands out as the preferred choice due to its ease of installation, impact resistance, durability, customization options, optical clarity, and resistance to various environmental factors.

Absolutely, without a doubt!

Plexiglass swimming pools are constructed from natural gases and possess a solid-state inertness.

The molecular structure of this material is highly stable, making it significantly stronger than glass swimming pools. In fact, plexiglass swimming pools are nearly 17 times stronger than their glass counterparts.

This strength is why plexiglass is more resistant to breakage compared to glass swimming pools.

Furthermore, plexiglass exhibits exceptional durability and can withstand higher water pressures with ease, surpassing the capabilities of glass swimming pools.

In terms of strength and resilience, acrylic swimming pools outshine glass swimming pools, providing a reliable and robust option for your aquatic enjoyment.

Certainly, you can.

The nature of plexiglass makes it relatively soft and allows for easy screwing.

It is also highly machinable, and screwing is often a necessary customization requirement for this type of panel.

However, it is important to use the appropriate tools to ensure optimal results when screwing into acrylic material.

The lifespan of a plexiglass swimming pool exposed to sunlight varies depending on factors such as the type of plexiglass used and the intensity of sunlight.

Additionally, the care and maintenance provided to the pool are crucial in determining its longevity.

In essence, certain types of plexiglass swimming pool panels can endure for many years without degradation or distortion.

Moreover, acrylic swimming pool grades may last for a number of years, experience slight distortion, but can be restored to their original condition and continue functioning as intended.

Generally, a plexiglass swimming pool can last anywhere from 15 to 50 years when exposed to the sun, depending on its grade, level of maintenance, and prevailing conditions.

Absolutely not!

Plexiglass swimming pools offer a wide range of color options beyond just clear shades.

We can provide up to 32 different colors to choose from.

This extensive color selection is crucial as it allows you to find the perfect color to suit your specific preferences and requirements.

Furthermore, you can even opt for a multicolored swimming pool plexiglass panel.

Multicolored panels feature more than two shades, adding versatility and aesthetic appeal to your swimming pool design.

The insulation capabilities of plexiglass and fiberglass swimming pools depend on various factors.

One crucial factor is the thickness of the materials, which significantly influences insulation performance.

However, in terms of their lambda values, plexiglass has a higher value compared to fiberglass.

The lambda value for plexiglass pool panels is approximately 0.19 watts per meter per Kelvin.

On the other hand, the specific lambda value for fiberglass varies based on factors such as double glazing and treatment methods.

When comparing equally thick sheets of plexiglass and glass, the glass material tends to provide better insulation than plexiglass.

Therefore, in terms of insulation properties, fiberglass has an advantage over acrylic in swimming pool applications.

The manufacturing process of plexiglass swimming pools may vary depending on the desired thickness and specifications.

Typically, thermoforming is the preferred method employed by many manufacturers to create this pool component.

The process involves the formation of two- and three-dimensional plexiglass sheets.

It begins with the design and redesign of the component to achieve the desired shape.

The material is heated to a pliable temperature, making it malleable.

Vacuum pressure, air pressure, or a combination of both is then applied to shape the mold.

Once removed from the mold, the formed sheet is allowed to cool, retaining its final shape.

If necessary, the sheet can be trimmed and fabricated to meet specific requirements.

Absolutely!

Plexiglass swimming pools offer a wide range of options and benefits that make them well-suited for indoor applications.

Their features make them an ideal choice for indoor swimming pools.

First and foremost, plexiglass panels provide high optical clarity, allowing for enhanced lighting within indoor spaces.

They are lightweight, making installation easy and eliminating the need for additional support.

Moreover, plexiglass is a safe material as it does not break or shatter, ensuring the prevention of accidents.

Furthermore, plexiglass swimming pools are highly customizable, allowing for personalized designs that can be tailored to match various aspects of the indoor space.

With these advantages, plexiglass swimming pools are an excellent choice for creating stunning indoor pool environments.

The method you employ to cut plexiglass swimming pool determines its susceptibility to cracking.

Although this material is durable, incorrect cutting techniques can lead to cracks.

To avoid this, here are some basic DIY steps for cutting plexiglass without causing damage:

Begin by ensuring you wear appropriate protective gear before starting the cutting process.

Use a fine-toothed saw blade specifically designed for cutting acrylic.

Mark the cutting line clearly on the plexiglass, using a ruler or a straight edge to ensure accuracy.

Apply gentle, steady pressure while cutting, allowing the blade to do the work without forcing it.

To reduce heat and prevent melting, periodically cool the cutting area with a water spray bottle.

If using a power tool, set it to a lower speed to prevent excessive heat buildup.

By following these guidelines and employing careful cutting techniques, you can successfully cut plexiglass swimming pool to size without causing any cracks.

While plexiglass is a durable material that is resistant to cracking, occasional cracks may still occur. It is important to address them promptly to prevent further damage. Here is a simple DIY method to seal a cracked plexiglass swimming pool:

Identify the crack and mark its ends with a small dot or line.

Use a drill with a fine drill bit to create tiny holes at both ends of the crack. This will help stop the crack from spreading further.

Apply a recommended acrylic adhesive or plexiglass repair kit along the crack, filling it in completely. Be careful not to apply too much adhesive to avoid excess spillage.

Use a soft cloth or sponge to wipe off any excess adhesive around the crack, ensuring a clean and smooth surface.

To further strengthen the repair, gently buff the sealed crack using a rotary polisher. This will help blend the repaired area with the surrounding plexiglass.

By following these steps, you can effectively seal a cracked plexiglass swimming pool, preventing the crack from worsening and avoiding the need for a full replacement.

Absolutely! Plexiglass is a highly customizable material, thanks to its machinability.

This means that there are various ways to modify and personalize your plexiglass swimming pool to meet your specific requirements.

Many manufacturers, such as WeProFab, offer the option to create highly customized pieces tailored to your needs.

To get a customized plexiglass swimming pool, all you need to do is provide a prototype or design concept that outlines your preferences and specifications.

The designers will then work to produce a customized replica of the plexiglass swimming pool based on the prototype you provided.

With this level of customization, you can have a unique and tailored plexiglass swimming pool that perfectly suits your vision.

There are several design options available in the market for plexiglass swimming pools, including both standard and customized units.

These designs vary in terms of size, shape, thickness, color shade, and other elements.

Here are some of the common designs you can find:

This design features a clear plexiglass material that allows you to see the entire pool.

This customized design gives the surface of the material a frosted or foggy glass appearance while still allowing light to pass through.

This made-to-order design creates a mirror-like surface that reflects images or specific objects.

This small-sized pool is designed to be placed outside the house and is portable, allowing you to change its position as desired.

To clean a plexiglass swimming pool, start by draining the water from the pool to identify any stubborn dirt or marks that require thorough cleaning.

If the pool is relatively large, you can use a pressure machine, but make sure to use lukewarm water, soap, or a recommended detergent along with a soft cloth.

Gently scrub the surface of the plexiglass swimming pool with the soft cloth to remove any accumulated dirt.

After scrubbing, rinse the surface with clean water and allow it to dry before refilling the pool.

Certainly! However, for best results, it's important to use the right paint for the task.

The choice of paint may vary, including options for translucent or opaque finishes.

Ensure that you use high-grade plexiglass paint or any suitable paint that bonds well with plexiglass.

When painting, apply the waterproof paint in regular sweeps, preferably using a spray method.

If you're looking to move away from traditional swimming pool designs, consider a plexiglass swimming pool, which offers a range of benefits and desirable features.

For custom plexiglass swimming pools, feel free to contact us.

Selexible is your premier choice for manufacturing top-quality plexiglass swimming pools. Plexiglass or Plexite Acrylic is the ideal material due to its exceptional clarity, weather resistance, and strength. As a leading plexiglass manufacturer in China, we specialize in producing a diverse range of high-quality plexiglass swimming pools.

At Selexible, we offer custom solutions tailored to your project specifications. Our expert team will work closely with you to create a custom plexiglass swimming pool that exceeds your expectations. In addition to our expert design services, we also provide installation and fabrication to ensure a seamless experience.

With Selexible, you can expect nothing less than a perfect and stunning plexiglass swimming pool. Our plexiglass swimming pools offer remarkable design versatility. Furthermore, plexiglass pools can be covered, providing additional usable space above the pool.

We manufacture plexiglass swimming pools in various styles, designs, and sizes. Choose from our three-sided plexiglass swimming pool, conventional rectangular plexiglass swimming pool, or L- and U-shaped plexiglass swimming pools. All our pools are securely installed at the jambs and sill.

Quality is our top priority at Selexible. Our plexiglass swimming pools meet rigorous standards, ensuring superior performance compared to many competitors. You can rely on Selexible for plexiglass swimming pools with excellent optical characteristics, weather resistance, light strength, and stability. Our engineers carefully select the appropriate thickness for optimal transparency during the manufacturing process.

When ordering from Selexible, rest assured about the quality. We provide free samples of our plexiglass swimming pools before large orders. With our wide stock of ready-to-ship plexiglass swimming pools, we can accommodate various requirements.

As a certified company, we take pride in offering Selexible plexiglass swimming pools. Trust us as your reliable supplier and manufacturer for all your swimming pool needs. Apart from plexiglass swimming pools, we also specialize in manufacturing plexiglass aquariums, plexiglass fish tanks, plexiglass skylights, and more.

Selexible has obtained various certifications such as SGS, CE, ISO 9001, ensuring our commitment to quality and customer satisfaction.

While a standard glass panel in a pool cannot be repaired if scratched or damaged, acrylic panels can be repairedon-site without the need to drain the entire pool.

Acrylic is a lightweight and durable material, weighing half as much as tempered glass.

Acrylic is highly malleable, making it easy to shape for radius designs.

When designing your acrylic panel, bonding technologies enable the creation of panels with unlimited sizes.

Impact resistant: Acrylic polymer exhibits 17 times greater impact resistance compared to tempered glass.

The design is engineered with a safety factor greater than 12.5.

With a minimum of 92% light transmission, acrylic maintains consistent transparency regardless of its thickness.

For more, you can download the pdf. as bellow

acrylic panels for swimming pools.pdf

acrylic panels for swimming pools.pdf

Acrylic panels offer superior durability compared to tempered glass, eliminating the risk of cracks or "spiderweb" dings in your window or custom pool design. When it comes to repairs and installation, acrylic surpasses glass. Unlike scratched glass, acrylic can be easily repolished and refinished without the need to drain water.

The refractive index of acrylic is the same as water, making the panel thickness virtually indiscernible when looking through it. It appears incredibly thin, almost like paper.

Outdoor acrylic pool panels exhibit exceptional durability, being highly resistant to breakage and impact. Acrylic's remarkable formability allows for limitless creative possibilities, enabling the transformation of any imaginative concept into reality.

With acrylic, size and scalability are virtually unlimited. Its outstanding visibility and clarity are unmatched, as it allows an impressive 92% light transmission. This makes it possible to create acrylic walls that beautifully merge with the surrounding environment in see-through swimming pools.

Size | Thickness | Size | Thickness |

1300*2500mm | 20~70mm | 1800*5000mm | 30~150mm |

1350*2650mm | 20~100mm | 2100*5500mm | 30~150mm |

1450*2700mm | 20~100mm | 3000*6200mm | 50~250mm |

1600*2600mm | 20~100mm | 3000*6700mm | 50~250mm |

1650*3150mm | 20~100mm | 3000*8200mm | 80~250mm |

2200*3200mm | 20~110mm | 3000*8700mm | 80~250mm |

1650*3500mm | 30~100mm | 3000*11500mm | 100~250mm |

2750*4250mm | 30~130mm | 3700*8100mm | 120~300mm |

| Item | Description |

| Material | Acrylic,100% virgin lucite or Mitsubishi |

| Color | Clear |

| Shape | Customized |

| Surface | High Surface Hardness |

| Light transmission | High light transmission(up to 96%) |

| Shipment | worldwide by sea or by air |

These panels are ideal for end placement, particularly when positioned towards scenic vistas. They are a popular selection for properties located alongside canals. Additionally, they are perfect for cantilevered pools. These panels are set within recesses on three sides, allowing for flexibility in water level placement, either below the top edge or opting for a "wet edge" effect for infinity pools.

Two panels are securely bonded at the corner using chemical bonding techniques. This design is also referred to as an "L-Shaped" window. The panels are skillfully set within recesses on three sides. You have the option to set the water level below the top edge or choose a "wet edge" configuration for infinity pools.

Three panels are expertly chemically bonded at two corners, creating a truly spectacular design suitable for premium properties. These panels are set within recesses on three sides, further enhancing their visual appeal. You have the flexibility to set the water level below the top edge or opt for a captivating "wet edge" effect in infinity pools.

This option is widely favored as a window for interior spaces, particularly those adjoining lounge or entertainment areas. The presence of a four-sided rebate ensures exceptional durability, making it ideal for large panels requiring additional strength.

Edge panels are elegantly designed as shallow 3-sided panels, serving as a stunning final touch to your pool. Flour panels, on the other hand, are particularly suitable for cantilevered pools, or they can be utilized to create captivating underwater skylights, adding a touch of allure to rooms and spaces located beneath the pool.

Swimming pools come in various shapes beyond square or rectangular designs! Acrylic can be skillfully molded to form both small and expansive curved sections, allowing for endless possibilities. You have the flexibility to choose between options with 3 or 4-sided rebates, providing further versatility in pool customization.

Absolutely.

When it comes to enhancing the efficiency, functionality, and quality of plexiglass swimming pool components in aquatic environments, various surface treatments are available.

Some popular coatings that can be applied to your acrylic pool walls include:

This treatment helps prevent moisture or fog from accumulating on the surface of the plexiglass pool panel, ensuring optimal clarity at all times.

This method reduces or eliminates excess or unwanted light, particularly beneficial for clear plexiglass panels or pools with lighting features.

Applying this coating helps protect the plexiglass surface from the damaging effects of ultraviolet rays, which can lead to distortion and discoloration.

This treatment prevents abrasive materials from causing unsightly marks on the plexiglass, maintaining its visual appeal.

These surface treatments contribute to the overall performance and longevity of plexiglass swimming pools.

Surely.

Here are all the reports and certificates that related with our acrylic sheets for swimming pool:

Chemical Resistant Report

Clarity Report

Data Sheet for Acrylic Sheets for Swimming Pool

Warranty Report for Acrylic Sheets for Swimming Pool

SGS Certificate of Transparency and Haza(Chinese version with translation)

SGS certificate of Aging by Light(Chinese version with translation)

* Export standard package or as clients' request to pack(usually in wooden or plastic pallets)

* We can deliver the goods or port or to door(customer's address) through sea shipping, air shipping or express.

Answer: Our acrylic pool windows are exclusively crafted using 100% Virgin Lucite MMA Raw Materials, ensuring UV resistance and exceptional quality.

Answer: Typically, our delivery time for Acrylic Pool Windows is 7-10 working days after receiving a 50% deposit payment. If you require additional machining services for the panel, we can utilize our CNT Machining Center to accommodate your specific drawing or machining requirements, which may slightly extend the delivery time. The final delivery time for Acrylic Pool Windows will be confirmed with you before you proceed with placing the order.

Answer: We provide a minimum 20-year warranty against any yellowing or crazing for our acrylic pool windows.

For the warranty , you can download the pdf. as bellow

warranty report for 30mm acrylic sheet.pdf

warranty report for 30mm acrylic sheet.pdf

The viewing area refers to the visible portion of the acrylic panel. While the panel itself is larger, as some of the acrylic is used for the rebates surrounding the windows, the viewing area is the specific section that can be seen.

Certain construction companies, pool builders, and acrylic installers may independently carry out their own calculations to determine the specifications for acrylic panels. In such cases, they provide us with comprehensive panel dimensions, including the desired thickness.

Alternatively, we calculate the appropriate thickness based on the information you provide, such as the dimensions of the viewing area, the distance between the water level and the top of the viewing area, and the number of rebates supporting the panel.

When we offer thickness recommendations, we generally follow a two-step process. Initially, we establish an estimated budget for your approval, and subsequently conduct a more detailed analysis to validate the initial calculations. The second stage may involve adjustments to the recommended thickness as necessary.

A Plexiglass Swimming Pool refers to a structure made from a transparent, shatterproof, and flexible thermoplastic material. It is specifically designed to create distinctive wall surfaces for various types of swimming pools, suitable for both indoor and outdoor installations. These pools are available in a wide array of options, including different designs, sizes, color shades, shapes, and more.

The ideal thickness of a Plexiglass Swimming Pool generally varies based on several factors, primarily architectural considerations. The shape and topography of the pool also play a significant role in determining the appropriate thickness for this pool component. Additionally, the projected water pressure is a crucial factor in determining the suitable thickness for a plexiglass swimming pool.

In most cases, the recommended thickness for this item typically falls within the range of 100mm to 150mm. This range is generally suitable for standard swimming pools. However, it is important to note that the actual thickness may undergo further evaluation and adjustment based on specific developmental considerations and individual factors.

When installing acrylic sheets for swimming pools, it is crucial to consider important aspects such as the size and design of the pool. These factors should align with the dimensions of the plexiglass to ensure a proper fit.

The installation process begins by using a suitable power tool to rebate the pool's surface, which depends on the nature of the pool's structure. Next, patching the rebates is essential to stabilize the anchor effect and enhance a unified core surface.

Using an epoxy paint, re-patch the rebates with silicone, taking care to prevent scratches on the plexiglass surface during installation. Before positioning the plexiglass panel, utilize a laser beam to ensure precise placement.

Once the panel is in position, reinforce all potential pressure points, particularly at the joints, and allow adequate time for curing. This ensures a strong and durable installation.

By following these steps, you can successfully install acrylic sheets for swimming pools, creating a visually appealing and long-lasting result.

The growing popularity of plexiglass indicates its superiority over fiberglass swimming pools in various aspects. One notable advantage is the ease of installation.

Plexiglass is lightweight, weighing almost half as much as fiberglass. This makes it easy to handle, transport, and install without requiring significant support.

Additionally, plexiglass exhibits superior impact resistance compared to fiberglass. It is approximately 17 times stronger, reducing the risk of cracking and breakage.

In terms of resilience, plexiglass outperforms fiberglass in multiple areas. It offers higher resistance to UV rays, corrosion, temperature changes, and weather conditions.

Plexiglass panels provide more options for customization, including variations in color shades, finishing, and shapes, allowing you to achieve your desired wall surface for the pool.

Optical clarity is also superior in plexiglass swimming pools, allowing up to 92% of light transmission compared to approximately 84% in fiberglass.

It's important to note that plexiglass has a softer surface than fiberglass, which makes it more susceptible to scratches when in contact with abrasive items.

Overall, plexiglass stands out as the preferred choice due to its ease of installation, impact resistance, durability, customization options, optical clarity, and resistance to various environmental factors.

Absolutely, without a doubt!

Plexiglass swimming pools are constructed from natural gases and possess a solid-state inertness.

The molecular structure of this material is highly stable, making it significantly stronger than glass swimming pools. In fact, plexiglass swimming pools are nearly 17 times stronger than their glass counterparts.

This strength is why plexiglass is more resistant to breakage compared to glass swimming pools.

Furthermore, plexiglass exhibits exceptional durability and can withstand higher water pressures with ease, surpassing the capabilities of glass swimming pools.

In terms of strength and resilience, acrylic swimming pools outshine glass swimming pools, providing a reliable and robust option for your aquatic enjoyment.

Certainly, you can.

The nature of plexiglass makes it relatively soft and allows for easy screwing.

It is also highly machinable, and screwing is often a necessary customization requirement for this type of panel.

However, it is important to use the appropriate tools to ensure optimal results when screwing into acrylic material.

The lifespan of a plexiglass swimming pool exposed to sunlight varies depending on factors such as the type of plexiglass used and the intensity of sunlight.

Additionally, the care and maintenance provided to the pool are crucial in determining its longevity.

In essence, certain types of plexiglass swimming pool panels can endure for many years without degradation or distortion.

Moreover, acrylic swimming pool grades may last for a number of years, experience slight distortion, but can be restored to their original condition and continue functioning as intended.

Generally, a plexiglass swimming pool can last anywhere from 15 to 50 years when exposed to the sun, depending on its grade, level of maintenance, and prevailing conditions.

Absolutely not!

Plexiglass swimming pools offer a wide range of color options beyond just clear shades.

We can provide up to 32 different colors to choose from.

This extensive color selection is crucial as it allows you to find the perfect color to suit your specific preferences and requirements.

Furthermore, you can even opt for a multicolored swimming pool plexiglass panel.

Multicolored panels feature more than two shades, adding versatility and aesthetic appeal to your swimming pool design.

The insulation capabilities of plexiglass and fiberglass swimming pools depend on various factors.

One crucial factor is the thickness of the materials, which significantly influences insulation performance.

However, in terms of their lambda values, plexiglass has a higher value compared to fiberglass.

The lambda value for plexiglass pool panels is approximately 0.19 watts per meter per Kelvin.

On the other hand, the specific lambda value for fiberglass varies based on factors such as double glazing and treatment methods.

When comparing equally thick sheets of plexiglass and glass, the glass material tends to provide better insulation than plexiglass.

Therefore, in terms of insulation properties, fiberglass has an advantage over acrylic in swimming pool applications.

The manufacturing process of plexiglass swimming pools may vary depending on the desired thickness and specifications.

Typically, thermoforming is the preferred method employed by many manufacturers to create this pool component.

The process involves the formation of two- and three-dimensional plexiglass sheets.

It begins with the design and redesign of the component to achieve the desired shape.

The material is heated to a pliable temperature, making it malleable.

Vacuum pressure, air pressure, or a combination of both is then applied to shape the mold.

Once removed from the mold, the formed sheet is allowed to cool, retaining its final shape.

If necessary, the sheet can be trimmed and fabricated to meet specific requirements.

Absolutely!

Plexiglass swimming pools offer a wide range of options and benefits that make them well-suited for indoor applications.

Their features make them an ideal choice for indoor swimming pools.

First and foremost, plexiglass panels provide high optical clarity, allowing for enhanced lighting within indoor spaces.

They are lightweight, making installation easy and eliminating the need for additional support.

Moreover, plexiglass is a safe material as it does not break or shatter, ensuring the prevention of accidents.

Furthermore, plexiglass swimming pools are highly customizable, allowing for personalized designs that can be tailored to match various aspects of the indoor space.

With these advantages, plexiglass swimming pools are an excellent choice for creating stunning indoor pool environments.

The method you employ to cut plexiglass swimming pool determines its susceptibility to cracking.

Although this material is durable, incorrect cutting techniques can lead to cracks.

To avoid this, here are some basic DIY steps for cutting plexiglass without causing damage:

Begin by ensuring you wear appropriate protective gear before starting the cutting process.

Use a fine-toothed saw blade specifically designed for cutting acrylic.

Mark the cutting line clearly on the plexiglass, using a ruler or a straight edge to ensure accuracy.

Apply gentle, steady pressure while cutting, allowing the blade to do the work without forcing it.

To reduce heat and prevent melting, periodically cool the cutting area with a water spray bottle.

If using a power tool, set it to a lower speed to prevent excessive heat buildup.

By following these guidelines and employing careful cutting techniques, you can successfully cut plexiglass swimming pool to size without causing any cracks.

While plexiglass is a durable material that is resistant to cracking, occasional cracks may still occur. It is important to address them promptly to prevent further damage. Here is a simple DIY method to seal a cracked plexiglass swimming pool:

Identify the crack and mark its ends with a small dot or line.

Use a drill with a fine drill bit to create tiny holes at both ends of the crack. This will help stop the crack from spreading further.

Apply a recommended acrylic adhesive or plexiglass repair kit along the crack, filling it in completely. Be careful not to apply too much adhesive to avoid excess spillage.

Use a soft cloth or sponge to wipe off any excess adhesive around the crack, ensuring a clean and smooth surface.

To further strengthen the repair, gently buff the sealed crack using a rotary polisher. This will help blend the repaired area with the surrounding plexiglass.

By following these steps, you can effectively seal a cracked plexiglass swimming pool, preventing the crack from worsening and avoiding the need for a full replacement.

Absolutely! Plexiglass is a highly customizable material, thanks to its machinability.

This means that there are various ways to modify and personalize your plexiglass swimming pool to meet your specific requirements.

Many manufacturers, such as WeProFab, offer the option to create highly customized pieces tailored to your needs.

To get a customized plexiglass swimming pool, all you need to do is provide a prototype or design concept that outlines your preferences and specifications.

The designers will then work to produce a customized replica of the plexiglass swimming pool based on the prototype you provided.

With this level of customization, you can have a unique and tailored plexiglass swimming pool that perfectly suits your vision.

There are several design options available in the market for plexiglass swimming pools, including both standard and customized units.

These designs vary in terms of size, shape, thickness, color shade, and other elements.

Here are some of the common designs you can find:

This design features a clear plexiglass material that allows you to see the entire pool.

This customized design gives the surface of the material a frosted or foggy glass appearance while still allowing light to pass through.

This made-to-order design creates a mirror-like surface that reflects images or specific objects.

This small-sized pool is designed to be placed outside the house and is portable, allowing you to change its position as desired.

To clean a plexiglass swimming pool, start by draining the water from the pool to identify any stubborn dirt or marks that require thorough cleaning.

If the pool is relatively large, you can use a pressure machine, but make sure to use lukewarm water, soap, or a recommended detergent along with a soft cloth.

Gently scrub the surface of the plexiglass swimming pool with the soft cloth to remove any accumulated dirt.

After scrubbing, rinse the surface with clean water and allow it to dry before refilling the pool.

Certainly! However, for best results, it's important to use the right paint for the task.

The choice of paint may vary, including options for translucent or opaque finishes.

Ensure that you use high-grade plexiglass paint or any suitable paint that bonds well with plexiglass.

When painting, apply the waterproof paint in regular sweeps, preferably using a spray method.

If you're looking to move away from traditional swimming pool designs, consider a plexiglass swimming pool, which offers a range of benefits and desirable features.

For custom plexiglass swimming pools, feel free to contact us.

Selexible is your premier choice for manufacturing top-quality plexiglass swimming pools. Plexiglass or Plexite Acrylic is the ideal material due to its exceptional clarity, weather resistance, and strength. As a leading plexiglass manufacturer in China, we specialize in producing a diverse range of high-quality plexiglass swimming pools.

At Selexible, we offer custom solutions tailored to your project specifications. Our expert team will work closely with you to create a custom plexiglass swimming pool that exceeds your expectations. In addition to our expert design services, we also provide installation and fabrication to ensure a seamless experience.

With Selexible, you can expect nothing less than a perfect and stunning plexiglass swimming pool. Our plexiglass swimming pools offer remarkable design versatility. Furthermore, plexiglass pools can be covered, providing additional usable space above the pool.

We manufacture plexiglass swimming pools in various styles, designs, and sizes. Choose from our three-sided plexiglass swimming pool, conventional rectangular plexiglass swimming pool, or L- and U-shaped plexiglass swimming pools. All our pools are securely installed at the jambs and sill.

Quality is our top priority at Selexible. Our plexiglass swimming pools meet rigorous standards, ensuring superior performance compared to many competitors. You can rely on Selexible for plexiglass swimming pools with excellent optical characteristics, weather resistance, light strength, and stability. Our engineers carefully select the appropriate thickness for optimal transparency during the manufacturing process.

When ordering from Selexible, rest assured about the quality. We provide free samples of our plexiglass swimming pools before large orders. With our wide stock of ready-to-ship plexiglass swimming pools, we can accommodate various requirements.

As a certified company, we take pride in offering Selexible plexiglass swimming pools. Trust us as your reliable supplier and manufacturer for all your swimming pool needs. Apart from plexiglass swimming pools, we also specialize in manufacturing plexiglass aquariums, plexiglass fish tanks, plexiglass skylights, and more.

Selexible has obtained various certifications such as SGS, CE, ISO 9001, ensuring our commitment to quality and customer satisfaction.

Contact Us