acrylic-15

Selexible Plastic

10pcs

350mm, 500mm, 700mm, 900mm, 1000mm, 1220mm

0.8mm, 1mm, 1.8mm, 2mm, 2.8mm, 3mm

| Availability: | |

|---|---|

| Quantity: | |

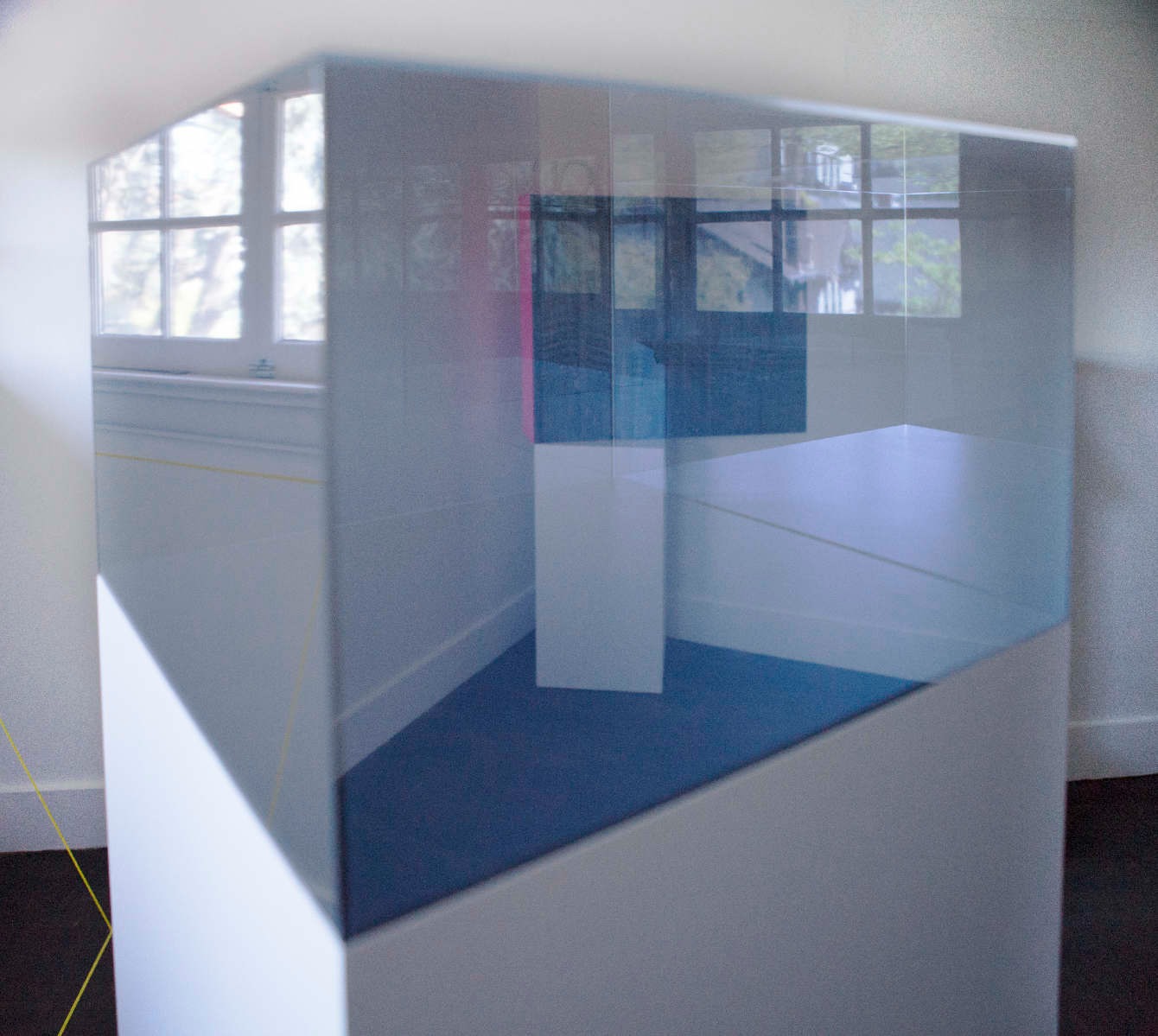

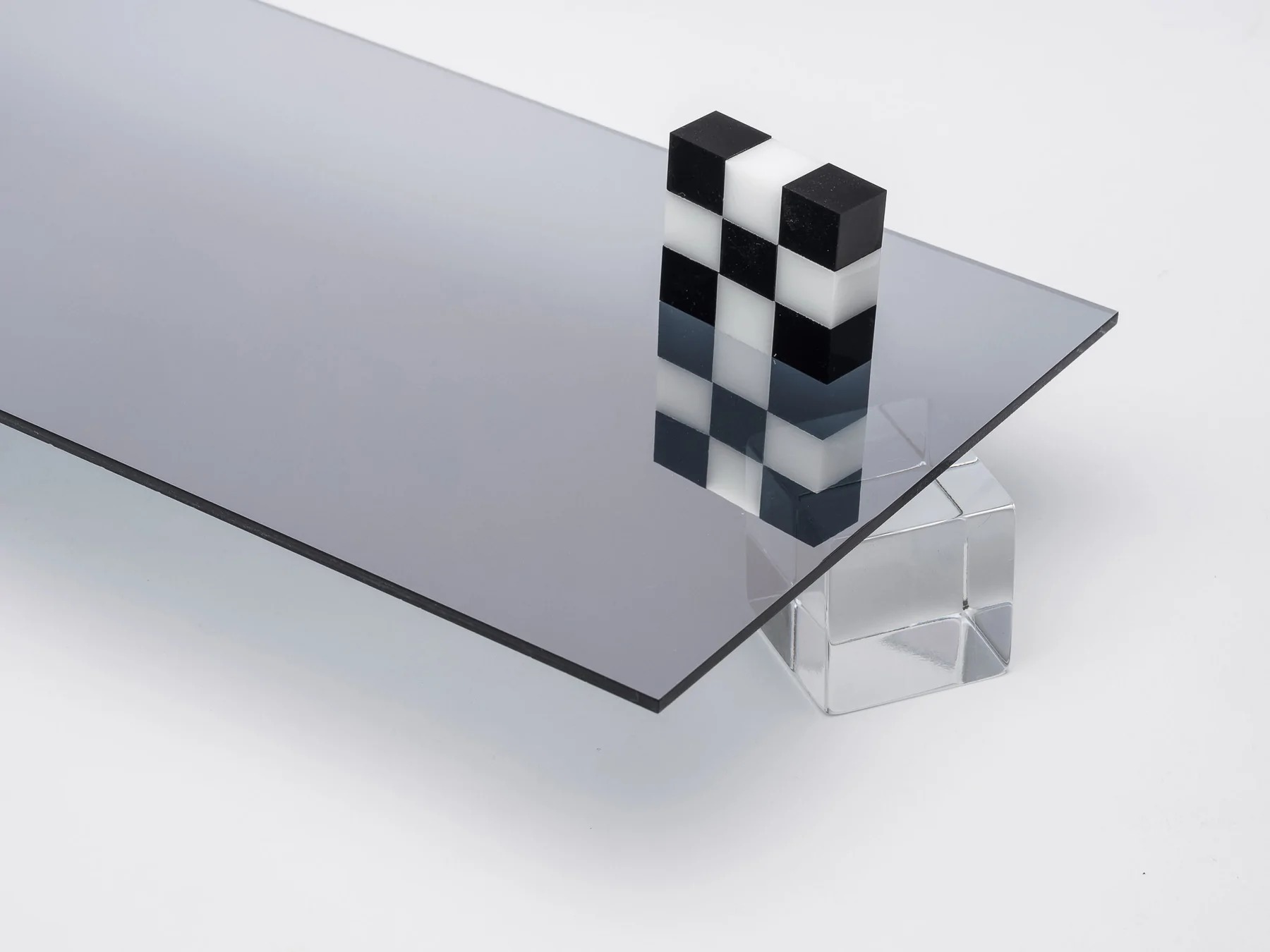

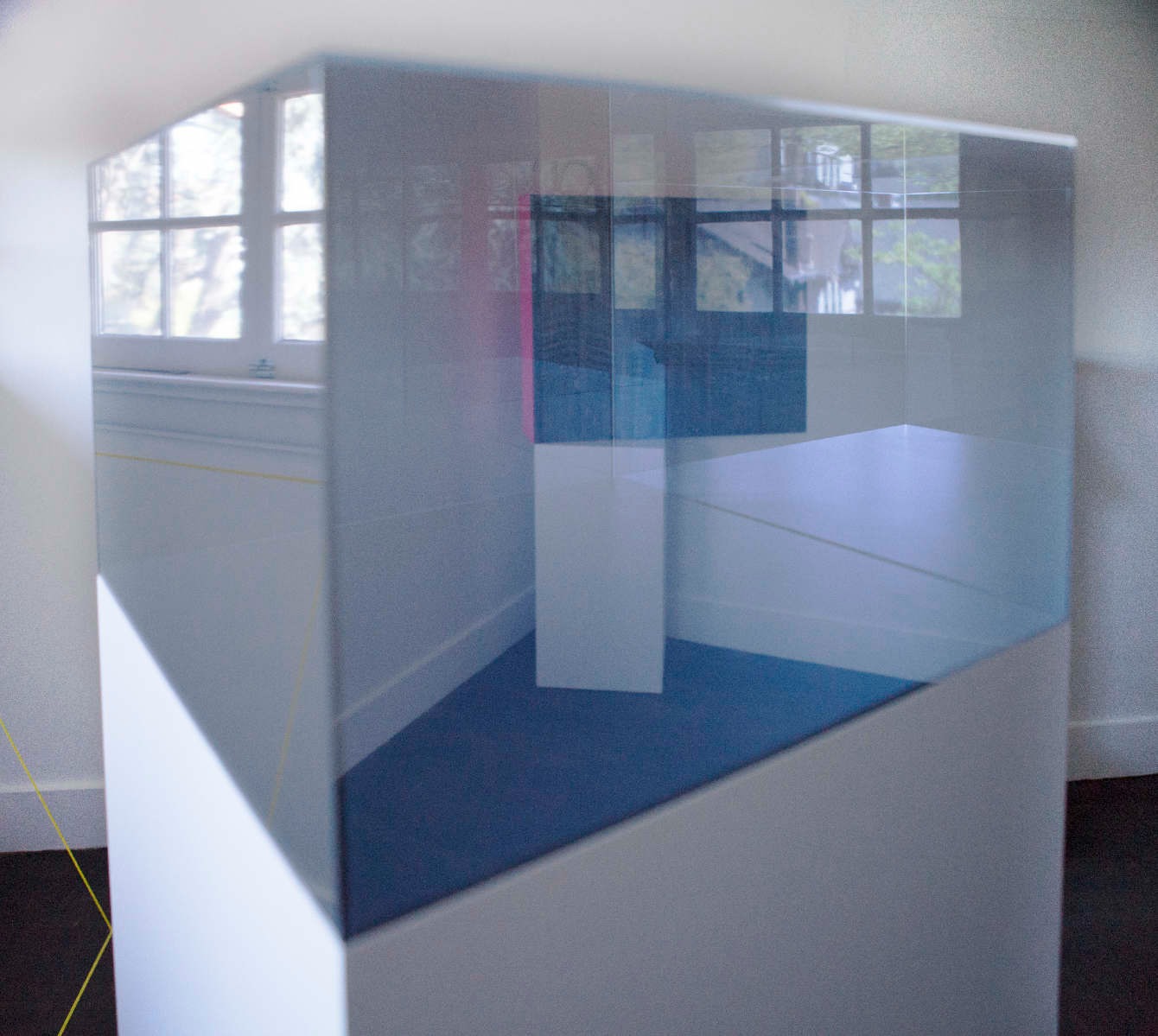

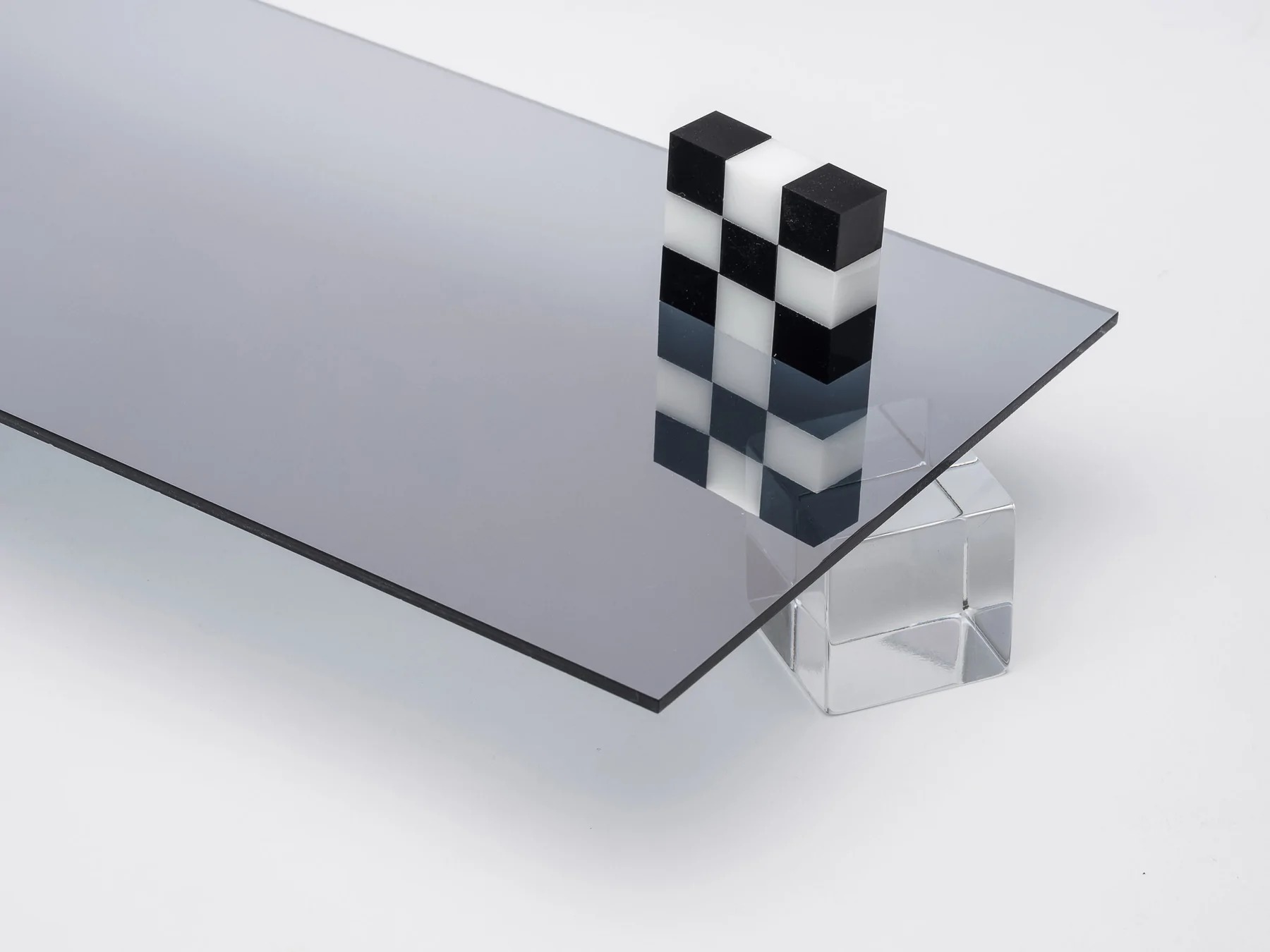

Two-way mirror acrylic sheet, also known as one-way mirror acrylic, is a type of plastic sheet that has a mirrored surface on one side and a transparent surface on the other. It is commonly used in architectural and design applications, as well as in theatrical and cinematic productions.

The way the two-way mirror works is by allowing light to pass through from one side while reflecting light back from the other side. When the light is brighter on one side of the sheet, that side will appear as a mirror, while the other side will appear transparent. However, when the light is brighter on the other side of the sheet, the opposite effect occurs, and the side that appeared as a mirror becomes transparent, while the previously transparent side becomes reflective.

Two-way mirror acrylic sheets are popular for use in various applications, such as privacy screens, observation windows, hidden cameras, and special effects in the entertainment industry. They are also commonly used in interior design for decorative purposes, such as for creating unique mirrors or displays.

In terms of maintenance, two-way mirror acrylic sheets can be cleaned using a mild soap solution and a soft cloth. However, it is important to avoid using abrasive materials or harsh chemicals that may scratch or damage the surface.

Two-way mirror acrylic sheet is a type of mirrored acrylic sheet that allows for two-way visibility. When one side is brightly lit and the other is dark, the side that is brightly lit will be reflective, while the side that is dark will be transparent. This effect is achieved through a special coating on one side of the acrylic sheet.

Here are some technical details about two-way mirror acrylic sheet:

Two-way mirror acrylic sheet is made of extruded acrylic, which is a type of thermoplastic material.

The coating on one side of the sheet is a thin layer of metal, typically aluminum, that has been vaporized and deposited onto the surface of the acrylic sheet. This coating is what gives the sheet its reflective properties.

Two-way mirror acrylic sheet comes in a variety of thicknesses, typically ranging from 1/8 inch to 1/4 inch.

Two-way mirror acrylic sheet is available in a range of sizes, from small sheets to large panels.

Two-way mirror acrylic sheet is lightweight and shatter-resistant, making it a durable alternative to traditional glass mirrors.

Two-way mirror acrylic sheet is commonly used in surveillance systems, hidden camera setups, and theatrical displays. It is also used in architecture and design for its unique reflective properties.

It's important to note that while two-way mirror acrylic sheet can provide privacy, it is not a completely opaque material and may not be suitable for all applications.

For more, you can check the PDF. as below

Two Way Mirror Acrylic Sheet MSDS(material safety data sheet).pdf

Two Way Mirror Acrylic Sheet MSDS(material safety data sheet).pdf Two Way Mirror Acrylic Sheet Data Sheet.pdf

Two Way Mirror Acrylic Sheet Data Sheet.pdf

Two-way mirror acrylic sheet is a versatile material that is often used in a variety of applications. Here are some of the common applications of two-way mirror acrylic sheet:

Two-way mirror acrylic sheet is often used in security applications such as surveillance rooms, interrogation rooms, and correctional facilities. It allows one-way visibility, enabling security personnel to observe suspects or inmates without being seen.

Two-way mirror acrylic sheet is used in various home decor applications, including mirrors, furniture, and decorative accents. It can be cut to size and shape, and its reflective surface creates a unique and modern aesthetic.

Two-way mirror acrylic sheet is used in retail displays, allowing customers to see products while concealing storage areas and backrooms. It can also be used to create interactive displays by incorporating video or lighting behind the mirror.

Two-way mirror acrylic sheet is used in the optics industry to create beam splitters, which split a single beam of light into two or more beams. It is also used in telescopes, camera lenses, and other optical applications.

Two-way mirror acrylic sheet is used in medical applications, including observation rooms and operating theaters. It allows doctors and medical personnel to observe patients without disturbing them.

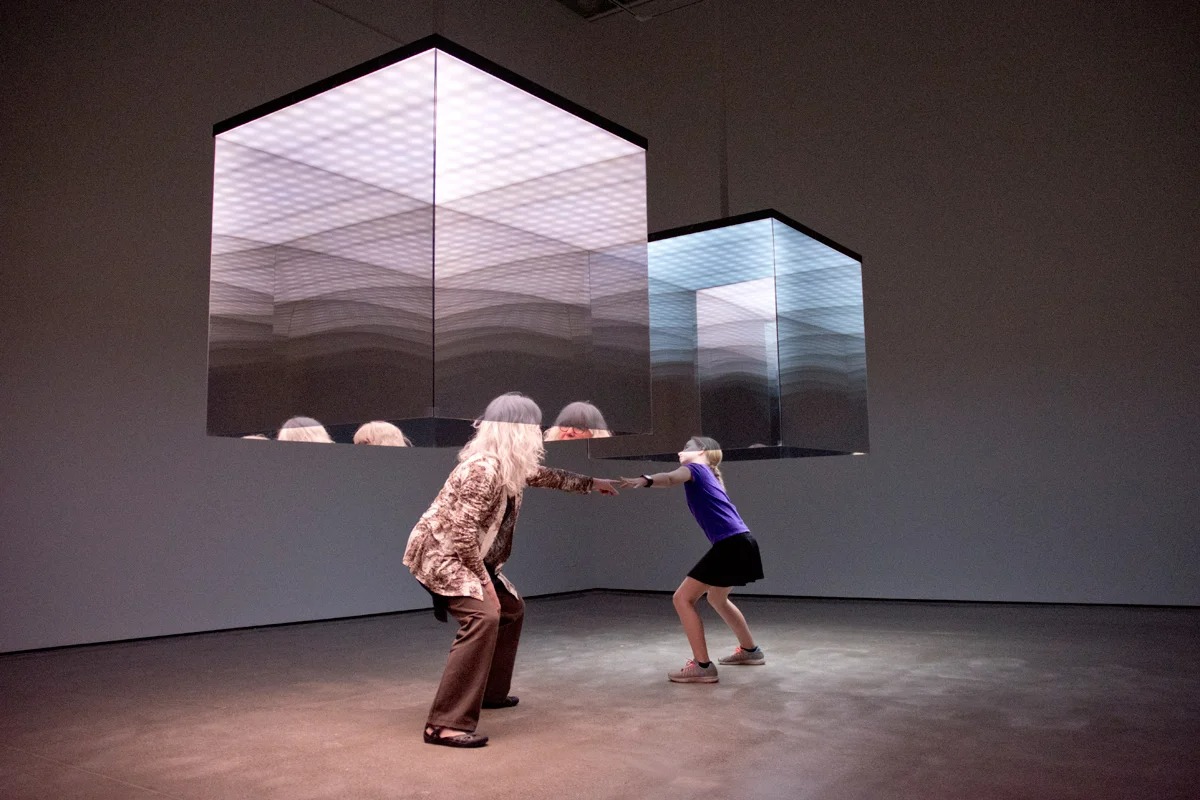

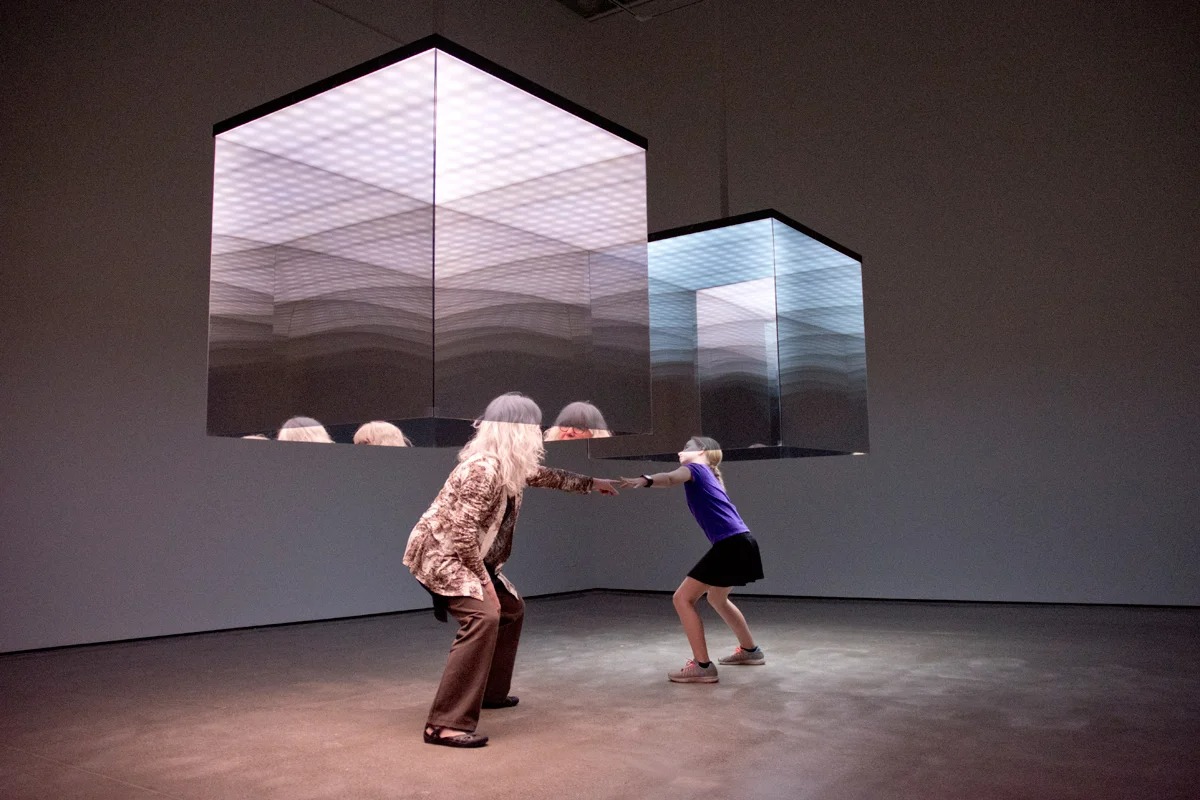

Two-way mirror acrylic sheet is used in art installations, creating unique visual effects and illusions. It can also be used in stage productions and movie sets to create special effects.

* Export standard package or as clients' request to pack(usually in wooden or plastic pallets)

* We can deliver the goods to port or to door(customer's address) through sea shipping, air shipping or express.

Cutting or engraving acrylic mirror can be done using a laser cutter or a CNC router. Here are some general steps for each method:

Create a design or file for the desired cut or engraving using vector-based software, such as Adobe Illustrator or Inkscape.

Place the acrylic mirror on the laser cutter bed and secure it in place.

Import the design file into the laser cutter software and adjust the settings for the material and desired cutting or engraving depth.

Begin the laser cutting or engraving process, ensuring that the acrylic mirror is not moved during the process.

Create a design or file for the desired cut or engraving using vector-based software, such as Adobe Illustrator or Inkscape.

Place the acrylic mirror on the CNC router bed and secure it in place.

Import the design file into the CNC router software and adjust the settings for the material and desired cutting or engraving depth.

Begin the CNC router cutting or engraving process, ensuring that the acrylic mirror is not moved during the process.

Regardless of the method used, it is important to wear appropriate personal protective equipment, such as safety glasses and gloves, and to ensure proper ventilation in the workspace.

To cut mirror acrylic with a Glowforge laser cutter, follow these steps:

Note that laser cutters can produce fumes when cutting acrylic, so make sure to work in a well-ventilated area and follow all safety instructions provided by the manufacturer. Also, mirror acrylic can be more difficult to cut due to the reflective surface, so it is important to make sure the material is well secured and the settings are adjusted appropriately.

Yes, we can. Please contact with us with the design draft or customized size, we will cut for you. Both CNC and laser cutting is available here.

Cleaning an acrylic mirror is easy and requires minimal effort. Here are some steps you can follow:

Start by removing any dust or debris from the surface of the mirror using a soft, dry cloth. Be gentle to avoid scratching the surface.

Next, prepare a solution of mild dish soap and warm water. Use a clean, soft cloth to dampen the solution and gently wipe the mirror surface. Avoid using harsh chemicals or abrasive materials, as they can scratch or damage the acrylic surface.

Rinse the mirror with clean water to remove any soap residue, and dry it with a soft, dry cloth or a microfiber cloth. Be sure to dry the surface thoroughly to prevent water spots or streaks.

If there are any stubborn spots or marks on the mirror, you can try using a specialized acrylic cleaner or a mixture of equal parts vinegar and water. Apply the cleaner to a soft cloth and gently rub the affected area, then rinse with clean water and dry as usual.

Remember to avoid using paper towels or rough materials, as they can scratch the surface of the acrylic mirror. With these simple steps, you can keep your acrylic mirror clean and looking great for years to come.

Installing an acrylic mirror sheet is a simple process that can be done by following these steps:

Measure the area where you want to install the acrylic mirror sheet. Use a tape measure to get the exact dimensions, and then transfer the measurements onto the mirror sheet using a pencil.

Cut the acrylic mirror sheet to size using a fine-toothed saw or a circular saw with a blade suitable for cutting acrylic. Make sure to wear protective gloves and eyewear during the cutting process.

Clean the surface where you will be installing the acrylic mirror sheet to remove any dust, dirt, or debris. Use a mild detergent solution and a soft cloth to wipe the surface, then let it dry completely.

Apply a double-sided adhesive tape or a silicone adhesive to the back of the acrylic mirror sheet. The adhesive should be evenly distributed along the entire back surface of the mirror sheet.

Carefully position the acrylic mirror sheet onto the cleaned surface, making sure that it is aligned properly with the edges and corners. Press the sheet firmly against the surface to ensure a good bond.

Allow the adhesive to cure for the recommended amount of time, which will depend on the type of adhesive used. Once the adhesive is fully cured, remove any protective film that may be covering the mirror surface.

With these simple steps, you can install an acrylic mirror sheet easily and quickly. Just be sure to take the proper safety precautions when cutting the sheet and handling the adhesive.

We are an factory of mirrored acrylic sheets in China, prices changing with your different request in sizes and thickness, colors, quantity and so on.

For an accurate quotation please contact with us without any hesitate, our sales team will help you to find the best solutions as what we have done during the past 18 years.

Two-way mirror acrylic sheet, also known as one-way mirror acrylic, is a type of plastic sheet that has a mirrored surface on one side and a transparent surface on the other. It is commonly used in architectural and design applications, as well as in theatrical and cinematic productions.

The way the two-way mirror works is by allowing light to pass through from one side while reflecting light back from the other side. When the light is brighter on one side of the sheet, that side will appear as a mirror, while the other side will appear transparent. However, when the light is brighter on the other side of the sheet, the opposite effect occurs, and the side that appeared as a mirror becomes transparent, while the previously transparent side becomes reflective.

Two-way mirror acrylic sheets are popular for use in various applications, such as privacy screens, observation windows, hidden cameras, and special effects in the entertainment industry. They are also commonly used in interior design for decorative purposes, such as for creating unique mirrors or displays.

In terms of maintenance, two-way mirror acrylic sheets can be cleaned using a mild soap solution and a soft cloth. However, it is important to avoid using abrasive materials or harsh chemicals that may scratch or damage the surface.

Two-way mirror acrylic sheet is a type of mirrored acrylic sheet that allows for two-way visibility. When one side is brightly lit and the other is dark, the side that is brightly lit will be reflective, while the side that is dark will be transparent. This effect is achieved through a special coating on one side of the acrylic sheet.

Here are some technical details about two-way mirror acrylic sheet:

Two-way mirror acrylic sheet is made of extruded acrylic, which is a type of thermoplastic material.

The coating on one side of the sheet is a thin layer of metal, typically aluminum, that has been vaporized and deposited onto the surface of the acrylic sheet. This coating is what gives the sheet its reflective properties.

Two-way mirror acrylic sheet comes in a variety of thicknesses, typically ranging from 1/8 inch to 1/4 inch.

Two-way mirror acrylic sheet is available in a range of sizes, from small sheets to large panels.

Two-way mirror acrylic sheet is lightweight and shatter-resistant, making it a durable alternative to traditional glass mirrors.

Two-way mirror acrylic sheet is commonly used in surveillance systems, hidden camera setups, and theatrical displays. It is also used in architecture and design for its unique reflective properties.

It's important to note that while two-way mirror acrylic sheet can provide privacy, it is not a completely opaque material and may not be suitable for all applications.

For more, you can check the PDF. as below

Two Way Mirror Acrylic Sheet MSDS(material safety data sheet).pdf

Two Way Mirror Acrylic Sheet MSDS(material safety data sheet).pdf Two Way Mirror Acrylic Sheet Data Sheet.pdf

Two Way Mirror Acrylic Sheet Data Sheet.pdf

Two-way mirror acrylic sheet is a versatile material that is often used in a variety of applications. Here are some of the common applications of two-way mirror acrylic sheet:

Two-way mirror acrylic sheet is often used in security applications such as surveillance rooms, interrogation rooms, and correctional facilities. It allows one-way visibility, enabling security personnel to observe suspects or inmates without being seen.

Two-way mirror acrylic sheet is used in various home decor applications, including mirrors, furniture, and decorative accents. It can be cut to size and shape, and its reflective surface creates a unique and modern aesthetic.

Two-way mirror acrylic sheet is used in retail displays, allowing customers to see products while concealing storage areas and backrooms. It can also be used to create interactive displays by incorporating video or lighting behind the mirror.

Two-way mirror acrylic sheet is used in the optics industry to create beam splitters, which split a single beam of light into two or more beams. It is also used in telescopes, camera lenses, and other optical applications.

Two-way mirror acrylic sheet is used in medical applications, including observation rooms and operating theaters. It allows doctors and medical personnel to observe patients without disturbing them.

Two-way mirror acrylic sheet is used in art installations, creating unique visual effects and illusions. It can also be used in stage productions and movie sets to create special effects.

* Export standard package or as clients' request to pack(usually in wooden or plastic pallets)

* We can deliver the goods to port or to door(customer's address) through sea shipping, air shipping or express.

Cutting or engraving acrylic mirror can be done using a laser cutter or a CNC router. Here are some general steps for each method:

Create a design or file for the desired cut or engraving using vector-based software, such as Adobe Illustrator or Inkscape.

Place the acrylic mirror on the laser cutter bed and secure it in place.

Import the design file into the laser cutter software and adjust the settings for the material and desired cutting or engraving depth.

Begin the laser cutting or engraving process, ensuring that the acrylic mirror is not moved during the process.

Create a design or file for the desired cut or engraving using vector-based software, such as Adobe Illustrator or Inkscape.

Place the acrylic mirror on the CNC router bed and secure it in place.

Import the design file into the CNC router software and adjust the settings for the material and desired cutting or engraving depth.

Begin the CNC router cutting or engraving process, ensuring that the acrylic mirror is not moved during the process.

Regardless of the method used, it is important to wear appropriate personal protective equipment, such as safety glasses and gloves, and to ensure proper ventilation in the workspace.

To cut mirror acrylic with a Glowforge laser cutter, follow these steps:

Note that laser cutters can produce fumes when cutting acrylic, so make sure to work in a well-ventilated area and follow all safety instructions provided by the manufacturer. Also, mirror acrylic can be more difficult to cut due to the reflective surface, so it is important to make sure the material is well secured and the settings are adjusted appropriately.

Yes, we can. Please contact with us with the design draft or customized size, we will cut for you. Both CNC and laser cutting is available here.

Cleaning an acrylic mirror is easy and requires minimal effort. Here are some steps you can follow:

Start by removing any dust or debris from the surface of the mirror using a soft, dry cloth. Be gentle to avoid scratching the surface.

Next, prepare a solution of mild dish soap and warm water. Use a clean, soft cloth to dampen the solution and gently wipe the mirror surface. Avoid using harsh chemicals or abrasive materials, as they can scratch or damage the acrylic surface.

Rinse the mirror with clean water to remove any soap residue, and dry it with a soft, dry cloth or a microfiber cloth. Be sure to dry the surface thoroughly to prevent water spots or streaks.

If there are any stubborn spots or marks on the mirror, you can try using a specialized acrylic cleaner or a mixture of equal parts vinegar and water. Apply the cleaner to a soft cloth and gently rub the affected area, then rinse with clean water and dry as usual.

Remember to avoid using paper towels or rough materials, as they can scratch the surface of the acrylic mirror. With these simple steps, you can keep your acrylic mirror clean and looking great for years to come.

Installing an acrylic mirror sheet is a simple process that can be done by following these steps:

Measure the area where you want to install the acrylic mirror sheet. Use a tape measure to get the exact dimensions, and then transfer the measurements onto the mirror sheet using a pencil.

Cut the acrylic mirror sheet to size using a fine-toothed saw or a circular saw with a blade suitable for cutting acrylic. Make sure to wear protective gloves and eyewear during the cutting process.

Clean the surface where you will be installing the acrylic mirror sheet to remove any dust, dirt, or debris. Use a mild detergent solution and a soft cloth to wipe the surface, then let it dry completely.

Apply a double-sided adhesive tape or a silicone adhesive to the back of the acrylic mirror sheet. The adhesive should be evenly distributed along the entire back surface of the mirror sheet.

Carefully position the acrylic mirror sheet onto the cleaned surface, making sure that it is aligned properly with the edges and corners. Press the sheet firmly against the surface to ensure a good bond.

Allow the adhesive to cure for the recommended amount of time, which will depend on the type of adhesive used. Once the adhesive is fully cured, remove any protective film that may be covering the mirror surface.

With these simple steps, you can install an acrylic mirror sheet easily and quickly. Just be sure to take the proper safety precautions when cutting the sheet and handling the adhesive.

We are an factory of mirrored acrylic sheets in China, prices changing with your different request in sizes and thickness, colors, quantity and so on.

For an accurate quotation please contact with us without any hesitate, our sales team will help you to find the best solutions as what we have done during the past 18 years.

Contact Us