acrylic-3

Selexible Plastic

10pcs

350mm, 500mm, 700mm, 900mm, 1000mm, 1220mm

0.8mm, 1mm, 1.8mm, 2mm, 2.8mm, 3mm

| Availability: | |

|---|---|

| Quantity: | |

Acrylic mirror sheet are produced by applying a metal finish to one side of the extruded acrylic sheet, then the mirror surface covered with a grey painted backing to protect.

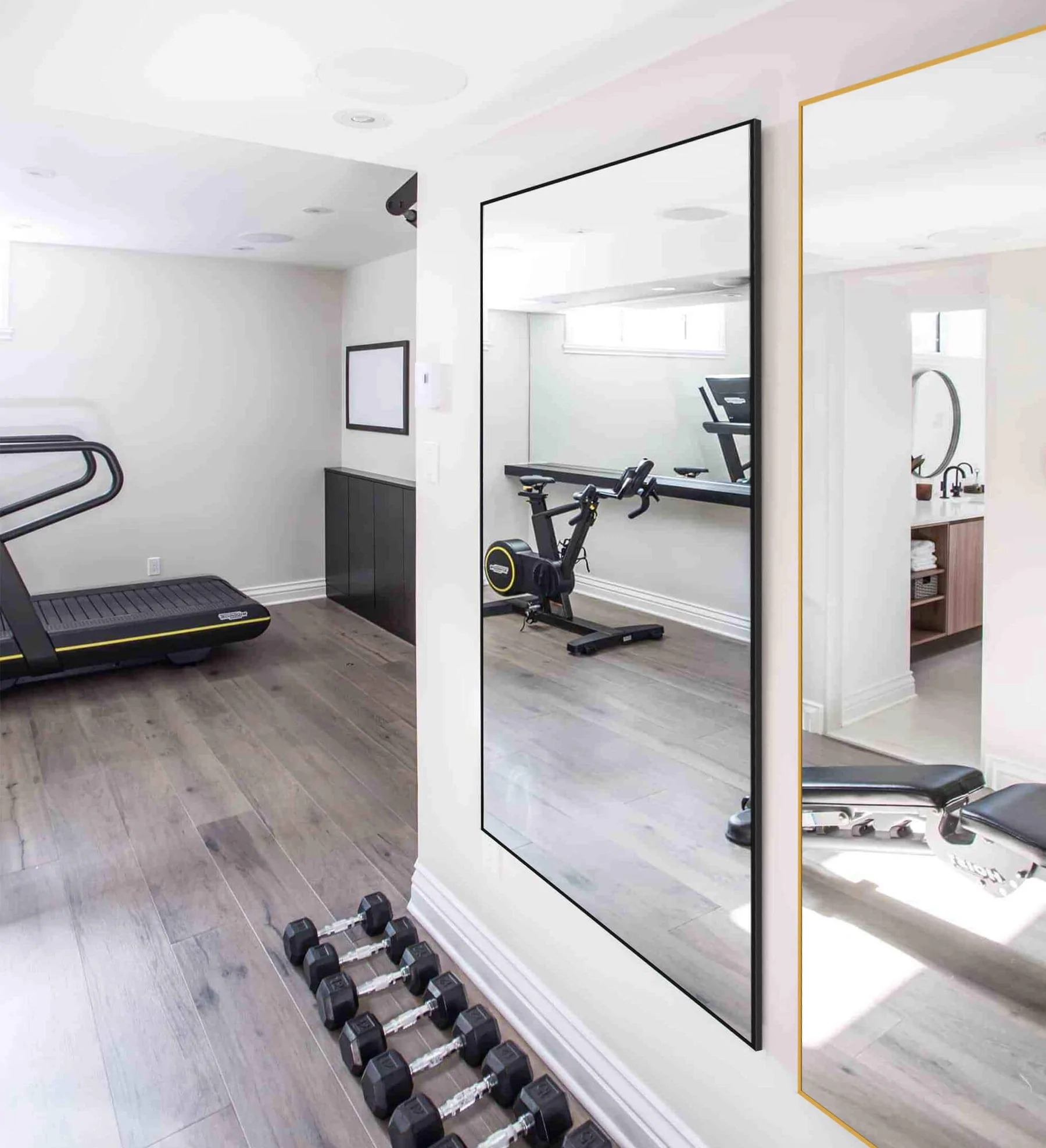

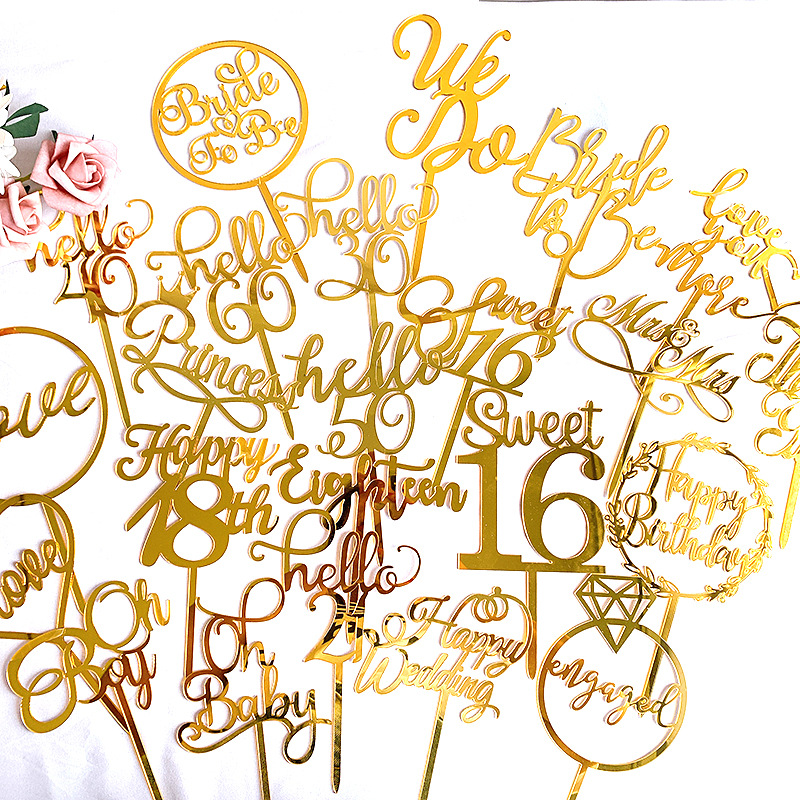

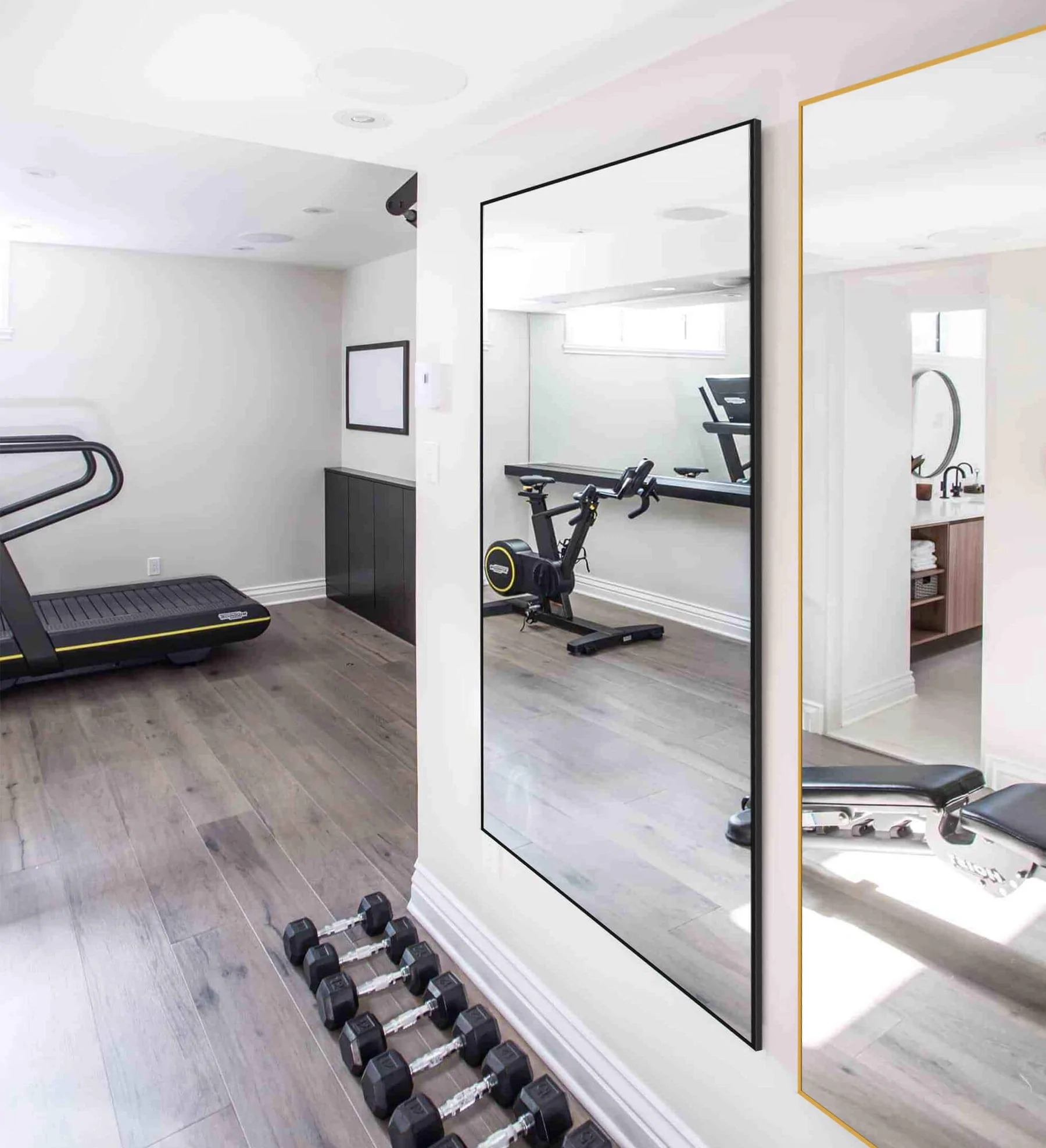

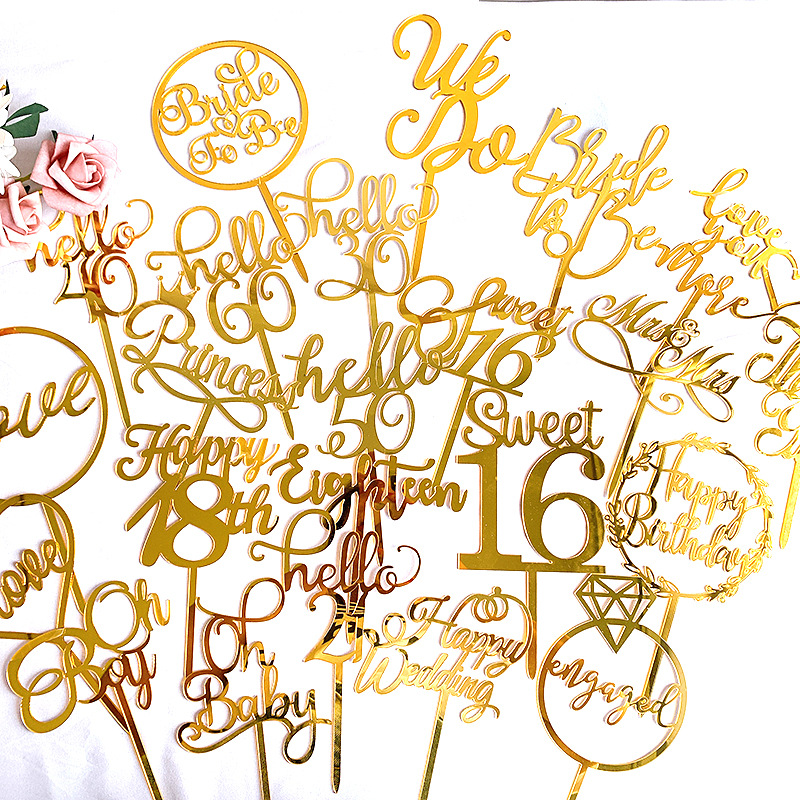

Acrylic mirror is an excellent alternative to the conventional glass mirrors. Acrylic mirror sheets are widely used in decorative displays, crafts, interior design applications and more. Mirrored acrylic is 50% lighter than glass, and many times more resistant to breakage and impact. Acrylic mirrors can be easily cut, drilled, shaped, and bent with a strip heater.

| Opacity | Opaque |

| Special Effect | Mirror |

| Surface Finish | Glossy |

| Transparency | 0% |

Common Thickness (net without protective) | 0.7mm, 0.8mm, 0.9mm, 1mm, 1.5mm, 1.8mm, 2mm, 2.8mm, 3mm |

| Widely Used Size | 610*760mm(2*3'), 1220*1830mm(4*6'), 1220*2440mm(4*8') |

| Base Acrylic Type | Extruded Acrylic |

| Masking | Clear PE Film or Brown Paper |

For more, you can check the PDF. as below

Black Mirror Acrylic MSDS(material safety data sheet).pdf

Black Mirror Acrylic MSDS(material safety data sheet).pdf Black Mirror Acrylic Data Sheet.pdf

Black Mirror Acrylic Data Sheet.pdf

* Export standard package or as clients' request to pack(usually in wooden or plastic pallets)

* We can deliver the goods to port or to door(customer's address) through sea shipping, air shipping or express.

Laser cutting can be used to cut acrylic mirrors of any shape while minimizing material waste. Laser cutting work by focusing a large amount of energy on a small, confined area, which then melts and vaporizes the material. It should be noted that the speed and light intensity must be well matched when cutting.

It is generally used to achieve precise straight-line cutting of one or more acrylic mirror sheets. When cutting the material with the mirror side down, you should keep a protective film between each two sheets, this will protect the paint back coating during the cutting process. If you only need to cut straight, this method is the fastest and cheaper.

Similar to laser cutting, it can cut the acrylic sheet according to the input graphics, but the cutting accuracy and effect are not as good as that of laser cutting. And more acrylic chips are produced during cutting, which wastes more material than other cutting methods.

In the absence of equipment, you can use a manual hook knife to mark the line to be cut on the acrylic mirrors, draw back and forth a few times. Then place one side on the desktop, one side hang in the air, the acrylic mirrors can be broken by hand along the scratches. If you want the edges to be neat, you can use sandpaper to polish the edges.

Reflectivity is highly dependent on wavelength. Per Glowforge, mirrored acrylic is opaque to the laser and non-reflective. However, copper, brass, and to a lesser extent silver, are all highly IR reflective and should not be used in the laser without surface treatment to prevent reflections back into the head.

Mirrored acrylic doesn’t need to by masked or cut in a certain orientation to protect the laser.

Yes, we can. Please contact with us with the design draft or customized size, we will cut for you. Both CNC and laser cutting is available here.

Use Brillianize or Novus products for cleaning and remove the scratch. Soap and water also works. Do not use Windex or 409. Also Lexan polycarbonate mirror is available by special order. The advantage is it will NOT break and can handle higher temperatures (120℃). It does good for police stations, psychiatric wards, prisons or other high breakage potential installations.

If you use screws for mounting, you will get distortion in the reflection. You NEED a Plexiglass Drill Bit for making the hole.

Trust us - you will break or crack the plastic with a metal bit.

Double Face Tape - easy way to mount.

Water-Based Contact Adhesive - a permanent solution to a FLAT surface.

We are an factory of mirrored acrylic sheets in China, prices changing with your different request in sizes and thickness, colors, quantity and so on.

For an accurate quotation please contact with us without any hesitate, our sales team will help you to find the best solutions as what we have done during the past 18 years.

Acrylic mirror sheet are produced by applying a metal finish to one side of the extruded acrylic sheet, then the mirror surface covered with a grey painted backing to protect.

Acrylic mirror is an excellent alternative to the conventional glass mirrors. Acrylic mirror sheets are widely used in decorative displays, crafts, interior design applications and more. Mirrored acrylic is 50% lighter than glass, and many times more resistant to breakage and impact. Acrylic mirrors can be easily cut, drilled, shaped, and bent with a strip heater.

| Opacity | Opaque |

| Special Effect | Mirror |

| Surface Finish | Glossy |

| Transparency | 0% |

Common Thickness (net without protective) | 0.7mm, 0.8mm, 0.9mm, 1mm, 1.5mm, 1.8mm, 2mm, 2.8mm, 3mm |

| Widely Used Size | 610*760mm(2*3'), 1220*1830mm(4*6'), 1220*2440mm(4*8') |

| Base Acrylic Type | Extruded Acrylic |

| Masking | Clear PE Film or Brown Paper |

For more, you can check the PDF. as below

Black Mirror Acrylic MSDS(material safety data sheet).pdf

Black Mirror Acrylic MSDS(material safety data sheet).pdf Black Mirror Acrylic Data Sheet.pdf

Black Mirror Acrylic Data Sheet.pdf

* Export standard package or as clients' request to pack(usually in wooden or plastic pallets)

* We can deliver the goods to port or to door(customer's address) through sea shipping, air shipping or express.

Laser cutting can be used to cut acrylic mirrors of any shape while minimizing material waste. Laser cutting work by focusing a large amount of energy on a small, confined area, which then melts and vaporizes the material. It should be noted that the speed and light intensity must be well matched when cutting.

It is generally used to achieve precise straight-line cutting of one or more acrylic mirror sheets. When cutting the material with the mirror side down, you should keep a protective film between each two sheets, this will protect the paint back coating during the cutting process. If you only need to cut straight, this method is the fastest and cheaper.

Similar to laser cutting, it can cut the acrylic sheet according to the input graphics, but the cutting accuracy and effect are not as good as that of laser cutting. And more acrylic chips are produced during cutting, which wastes more material than other cutting methods.

In the absence of equipment, you can use a manual hook knife to mark the line to be cut on the acrylic mirrors, draw back and forth a few times. Then place one side on the desktop, one side hang in the air, the acrylic mirrors can be broken by hand along the scratches. If you want the edges to be neat, you can use sandpaper to polish the edges.

Reflectivity is highly dependent on wavelength. Per Glowforge, mirrored acrylic is opaque to the laser and non-reflective. However, copper, brass, and to a lesser extent silver, are all highly IR reflective and should not be used in the laser without surface treatment to prevent reflections back into the head.

Mirrored acrylic doesn’t need to by masked or cut in a certain orientation to protect the laser.

Yes, we can. Please contact with us with the design draft or customized size, we will cut for you. Both CNC and laser cutting is available here.

Use Brillianize or Novus products for cleaning and remove the scratch. Soap and water also works. Do not use Windex or 409. Also Lexan polycarbonate mirror is available by special order. The advantage is it will NOT break and can handle higher temperatures (120℃). It does good for police stations, psychiatric wards, prisons or other high breakage potential installations.

If you use screws for mounting, you will get distortion in the reflection. You NEED a Plexiglass Drill Bit for making the hole.

Trust us - you will break or crack the plastic with a metal bit.

Double Face Tape - easy way to mount.

Water-Based Contact Adhesive - a permanent solution to a FLAT surface.

We are an factory of mirrored acrylic sheets in China, prices changing with your different request in sizes and thickness, colors, quantity and so on.

For an accurate quotation please contact with us without any hesitate, our sales team will help you to find the best solutions as what we have done during the past 18 years.

Contact Us